The 930 Resurrection Project

The 930 Resurrection Project

With over 20 years of expertise in 4×4 swaps and automotive electronics, and the invaluable help of my father, a mechanic with 50 years of experience working with air-cooled engines, I embarked on the journey of restoring a Porsche 930 from the ground up. Every screw, every nut, and every washer was inspected and replaced or restored as necessary to ensure the vehicle’s authenticity and performance. This restoration project aims to preserve the Porsche legacy while ensuring the car operates at its best for the modern age.

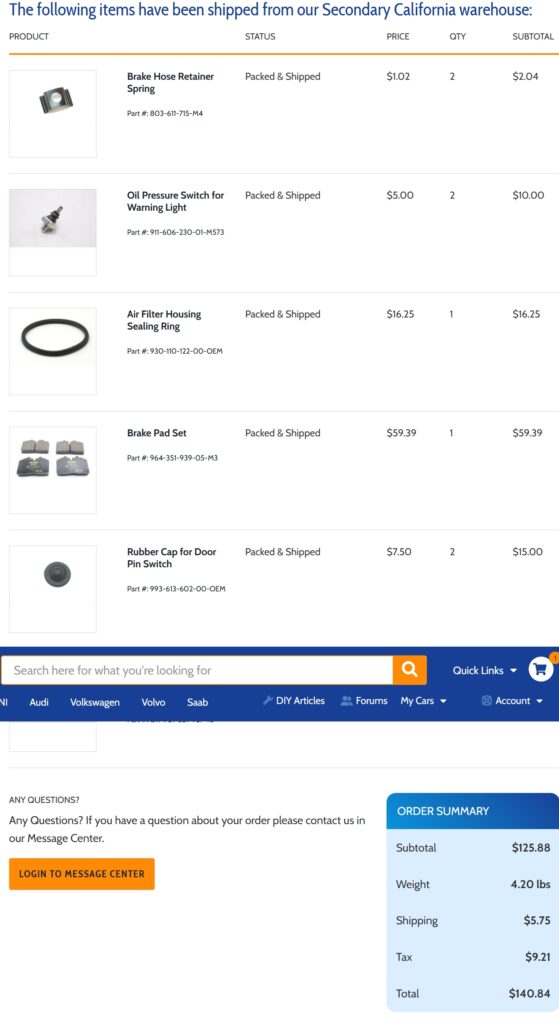

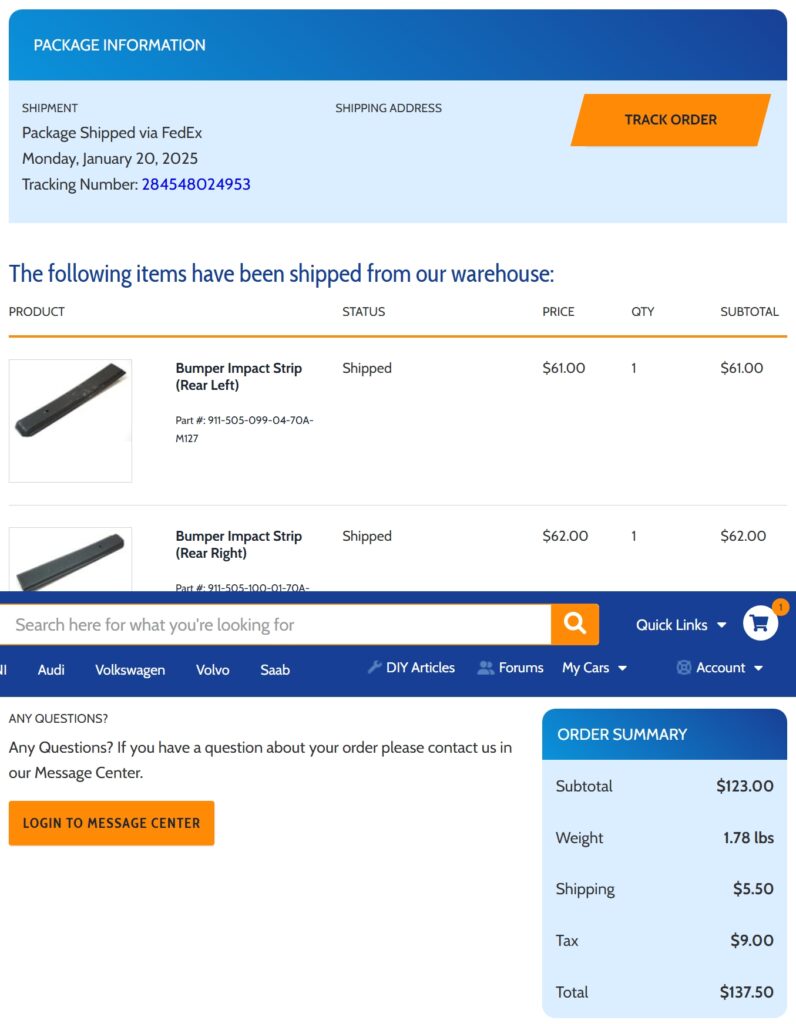

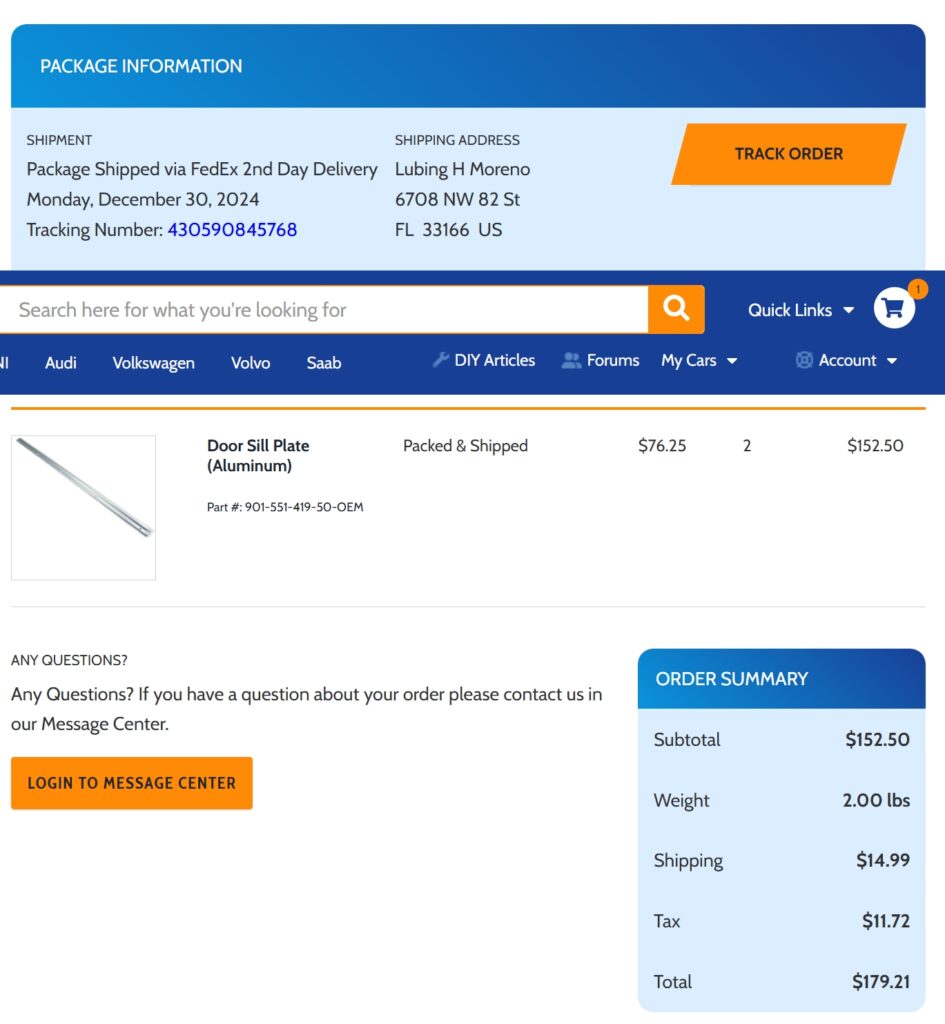

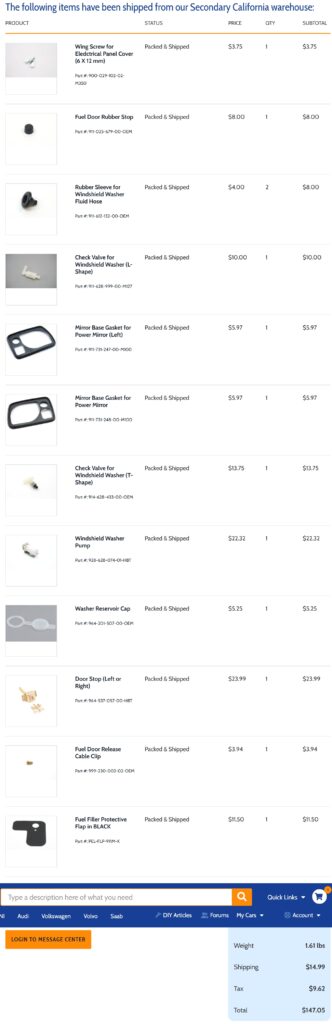

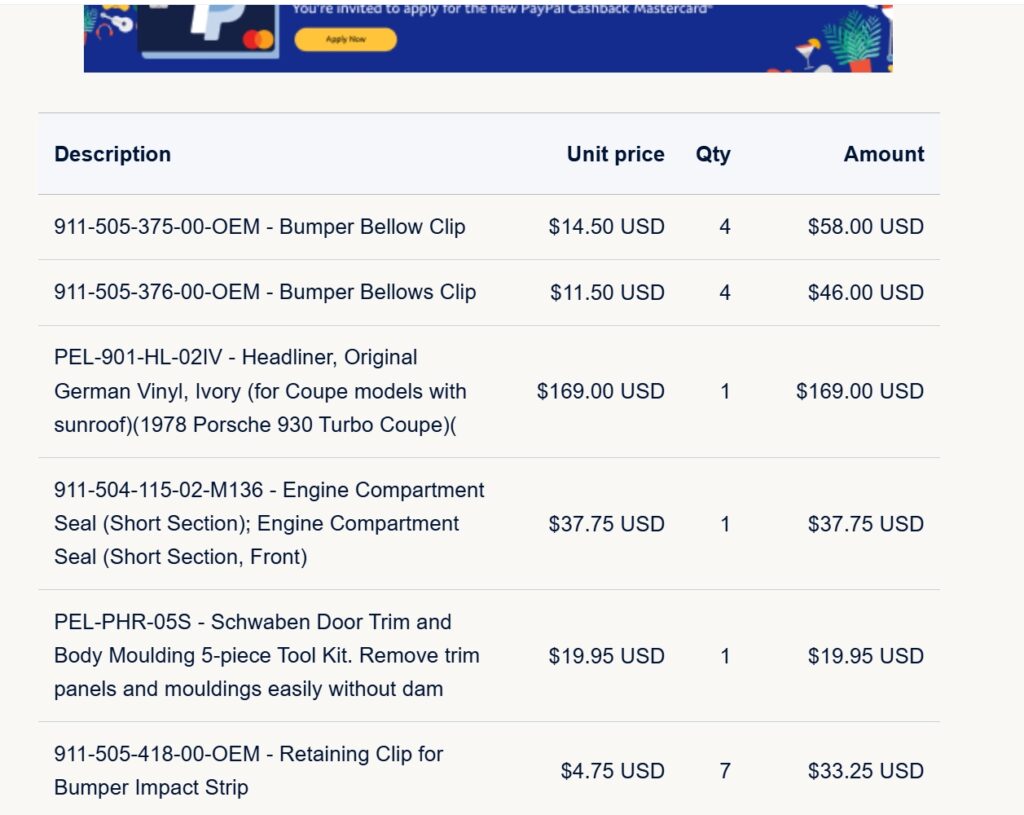

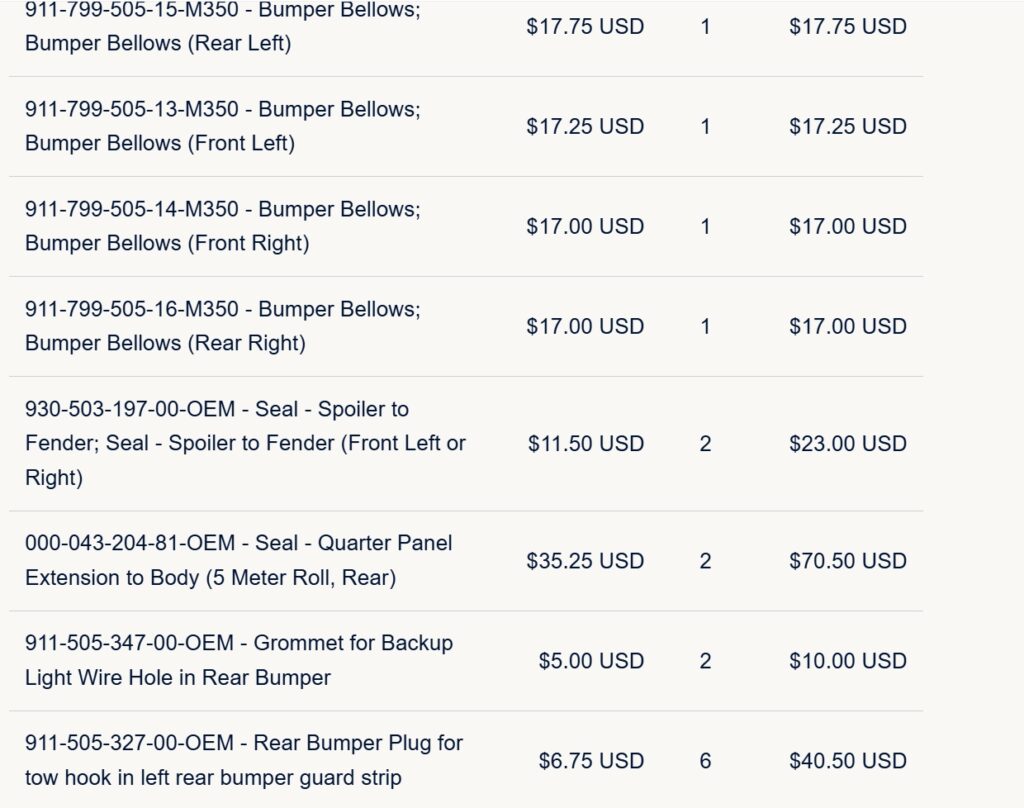

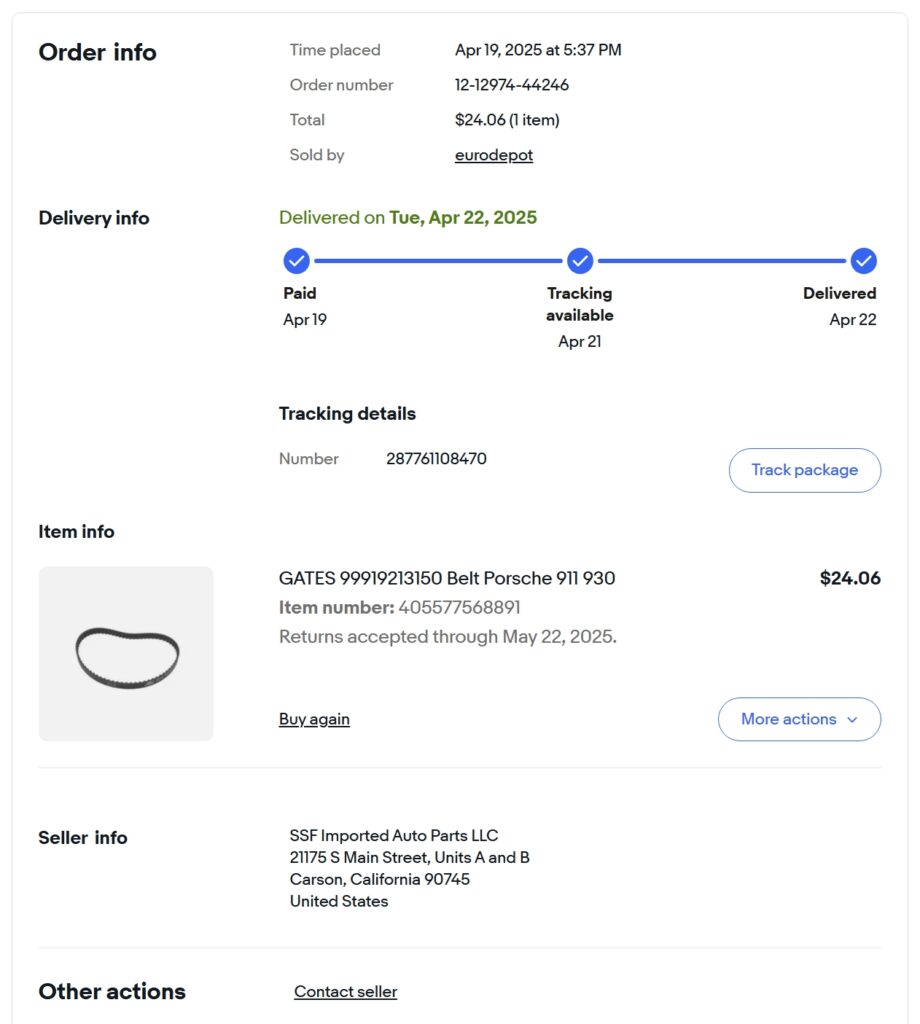

As part of the restoration process of this 930, all rubber components were replaced with OEM parts to ensure both functionality and safety.

This included all weatherstrips, brake hoses, fuel hoses, exterior rubber seals, and even the bumper accordions. Additionally, the side rubbers of the wheel wells (guardrock) and rear bumper seals were all renewed.

Over time, rubber parts lose their flexibility, tend to crack, and lose both their functionality and aesthetic appeal. For critical components like the brake lines and fuel hoses, safety and reliability are paramount. Not only do these parts enhance the appearance of the car, but they also provide the security needed for safe driving.

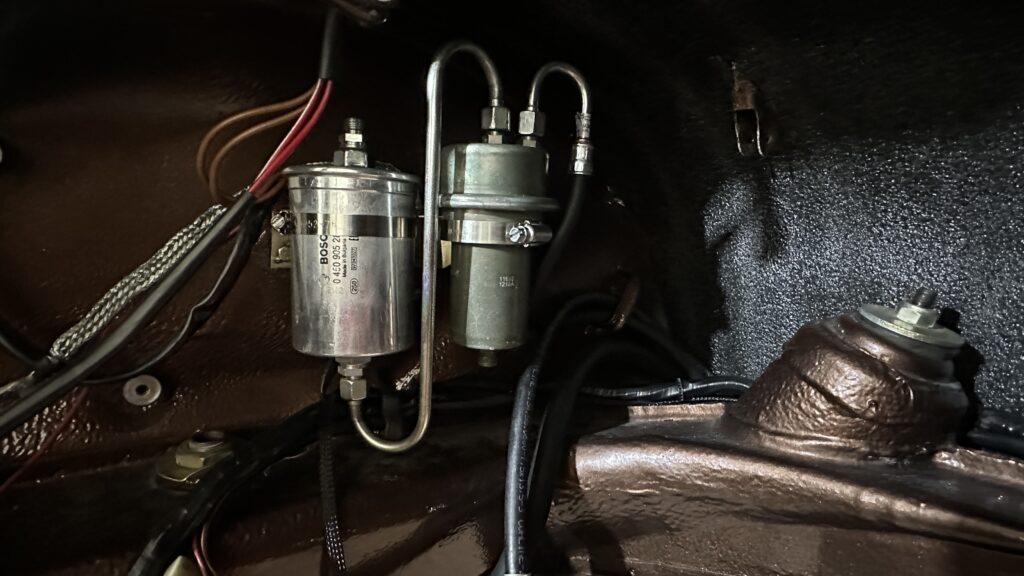

Fuel pumps and other fuel system components were replaced, including a new fuel filter and fuel retaining seal, ensuring optimal fuel delivery and preventing leaks.

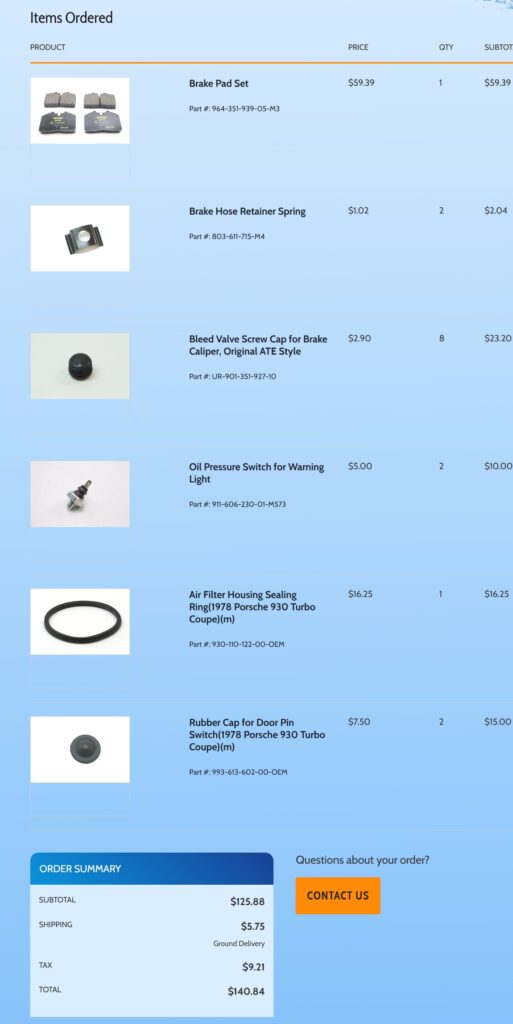

The brake system was completely restored, including the brake hoses and necessary components to guarantee safety and performance.

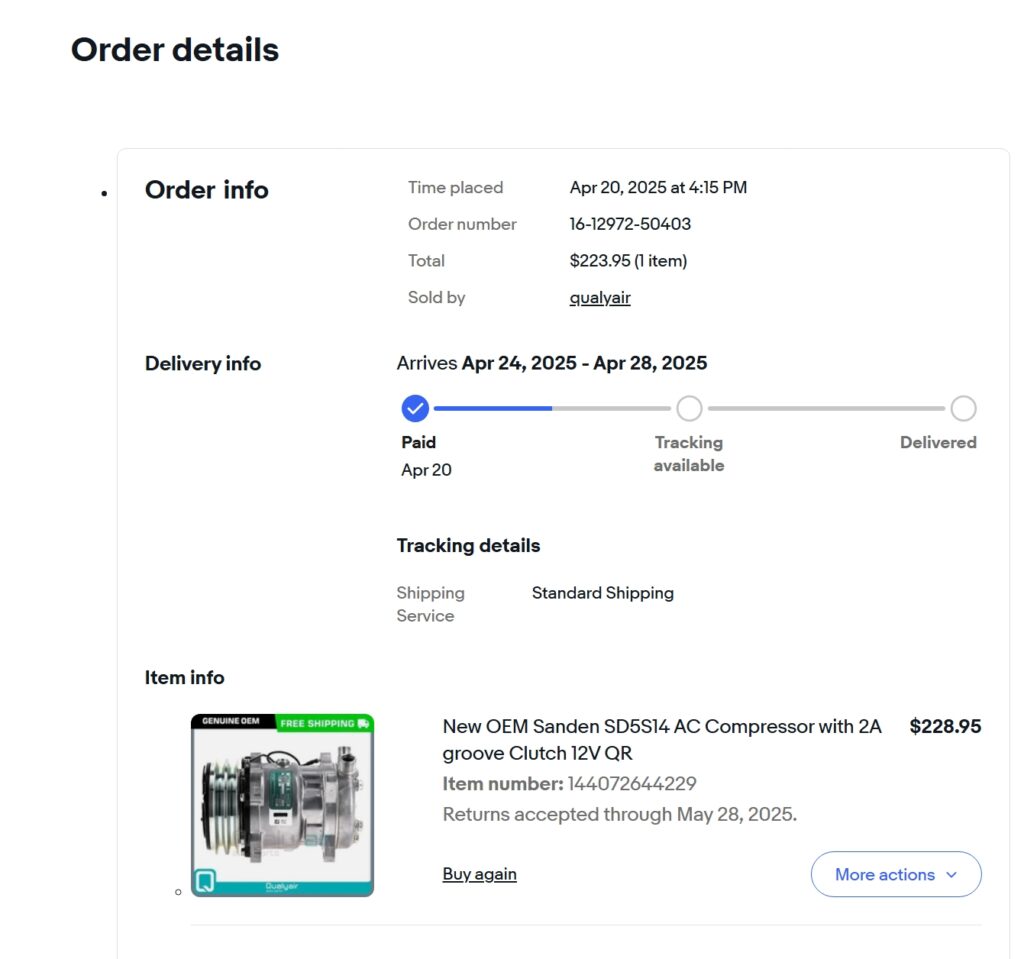

A new A/C dryer, A/C compressor, A/C hoses, and a new condenser were installed, along with all related components to restore the climate control system to optimal working conditions. An adjustable TXV valve was also added to better manage the refrigerant flow, improving cooling efficiency.

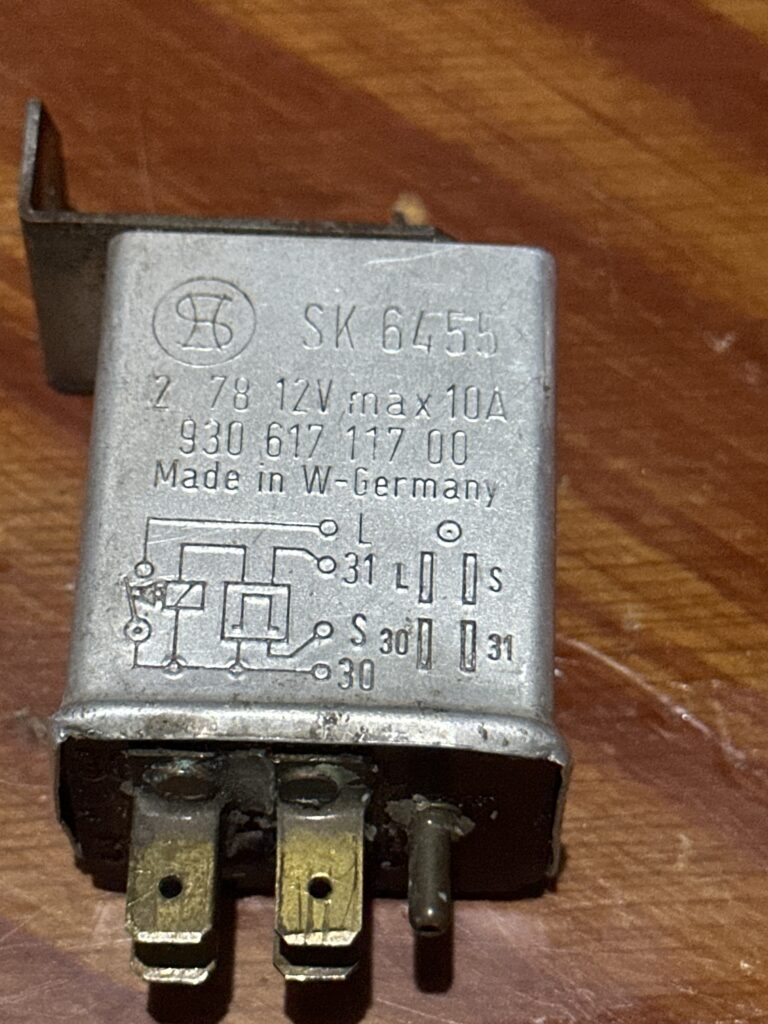

All relays were replaced with new ones to prevent electrical issues, especially in older components that often fail with age. While not all switches were replaced, the ones that showed signs of wear or failure were upgraded to ensure reliable, fault-free operation for decades to come.

The tires were replaced with new ones, ensuring better traction and handling.

Suspension and steering components were replaced to ensure smooth handling and improved driving comfort.

The electrical system was thoroughly inspected, and any problematic harnesses were replaced with new wiring, as these cars are known for having wiring differences over the years.

The headlamp and windshield washer pumps were also replaced to restore full functionality.

The engine was completely disassembled, and bearings, piston rings, cylinder seals, injectors were replaced with new components. A new turbo was also installed to improve performance and efficiency. The warm-up regulator was fully restored, along with the auxiliary air intake system.

Every component was tested, restored, or replaced as necessary to ensure the vehicle runs like new.

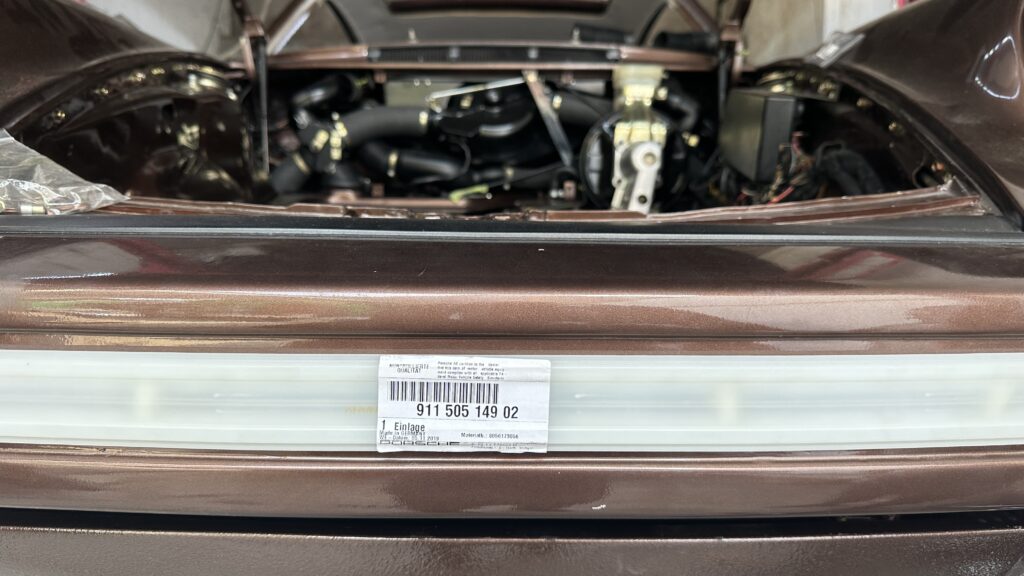

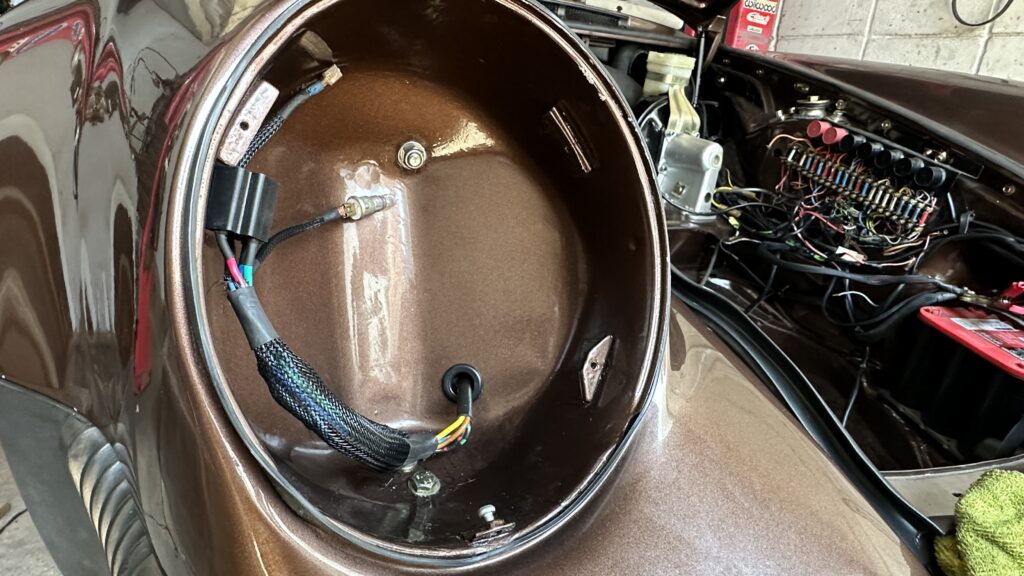

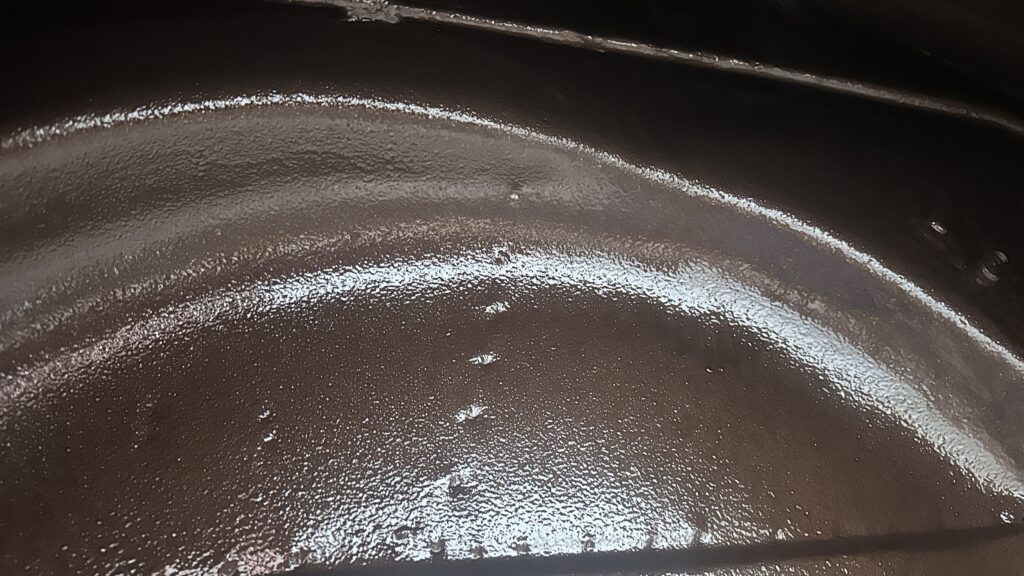

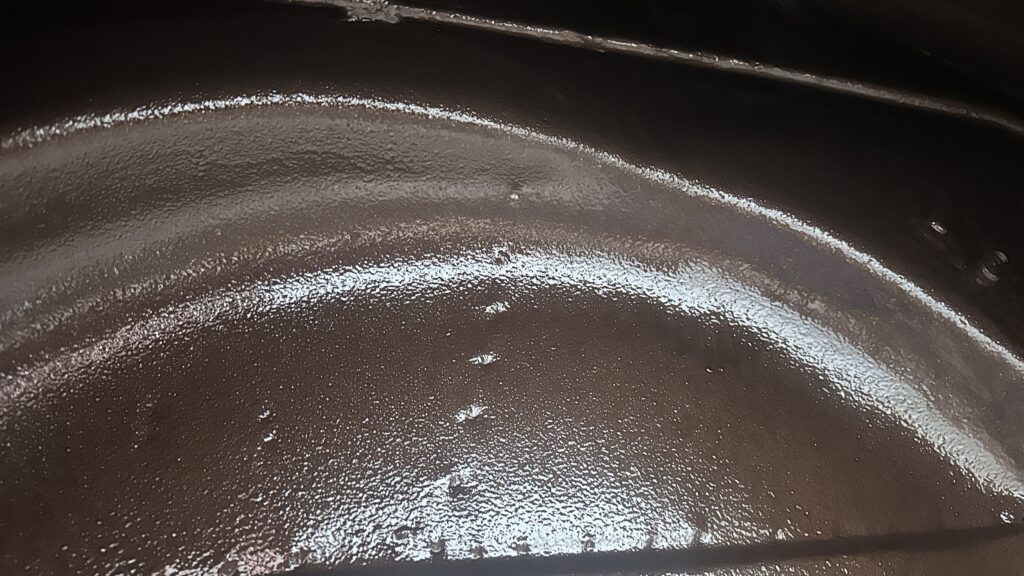

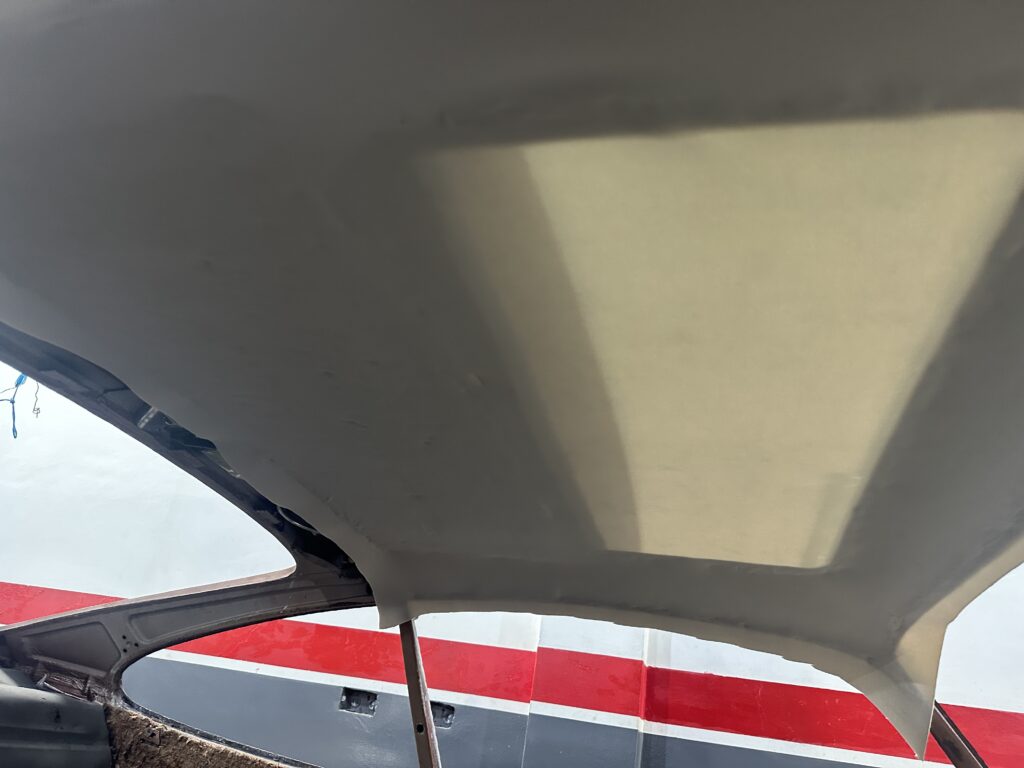

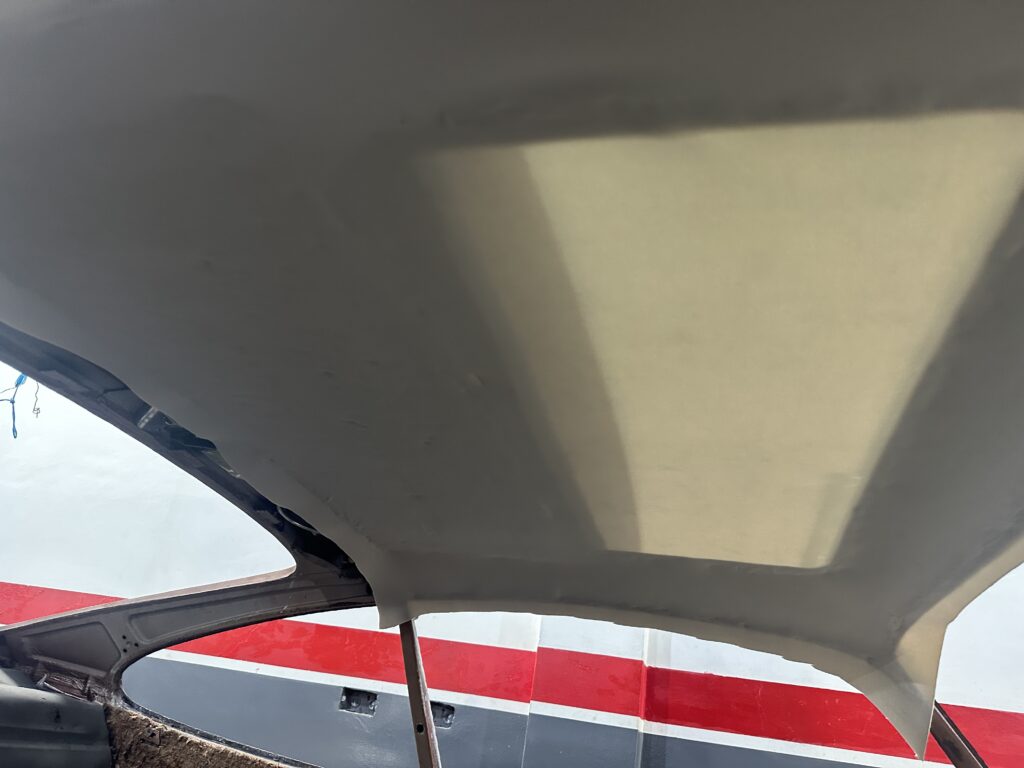

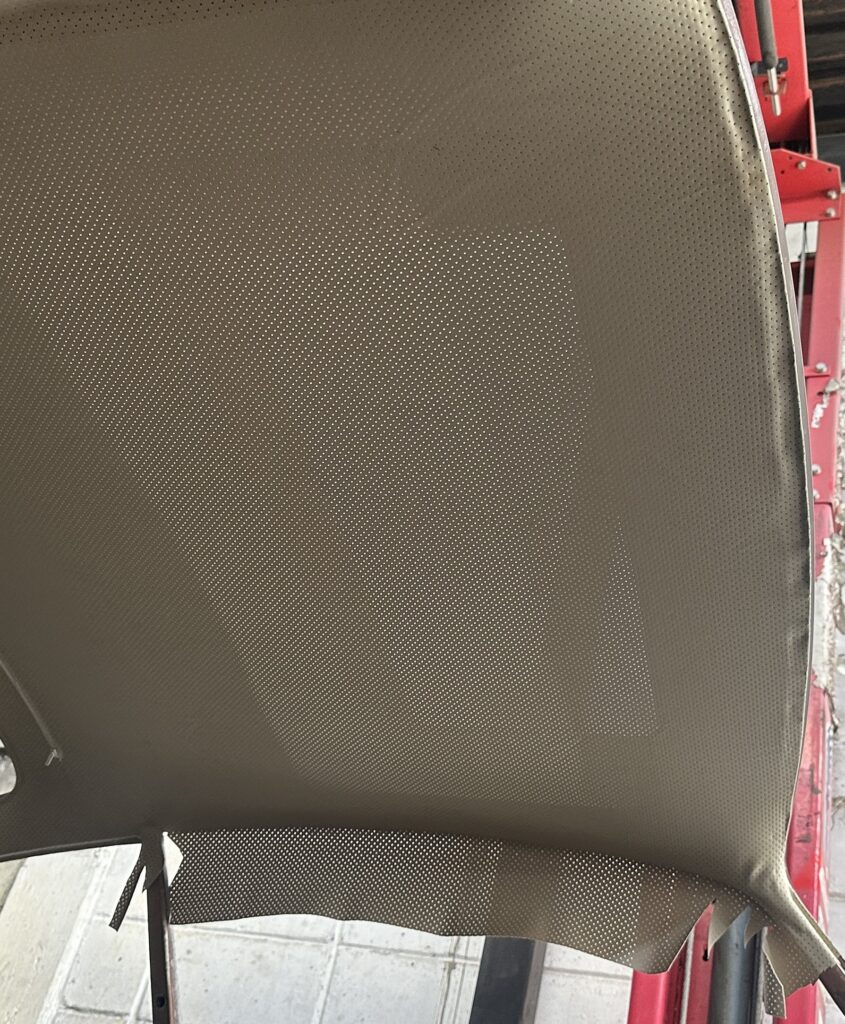

The body was meticulously restored, stripped down to bare metal, and painted from scratch. No areas were left with mismatched or residual paint, as the vehicle was completely disassembled and restored in its entirety.

Body

The work on the body was done from bare metal, as shown in the images. The body was in excellent condition, as seen in the first image. After being painted with Brown Metallic, the result can be observed in the video.»

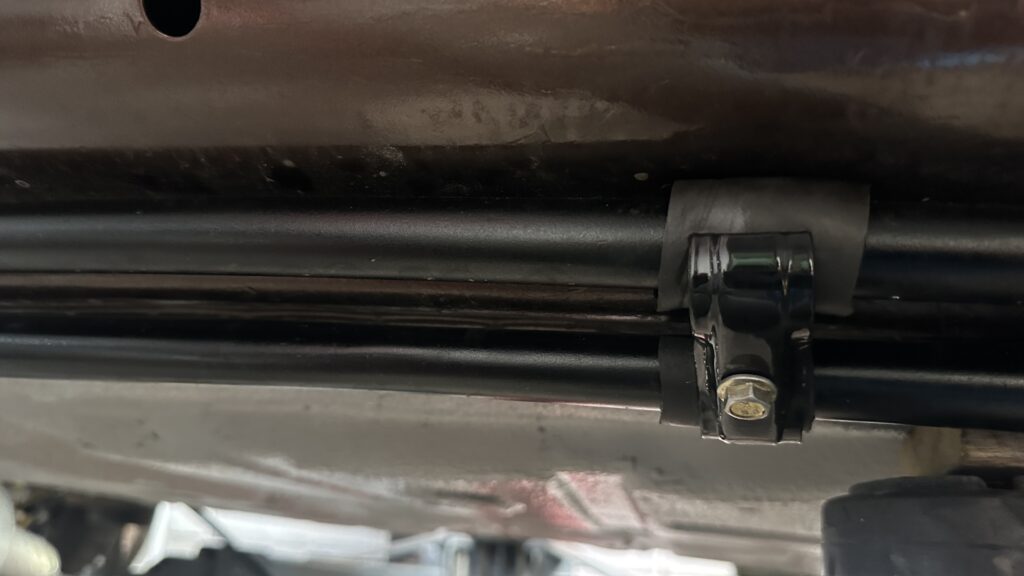

Fuel System

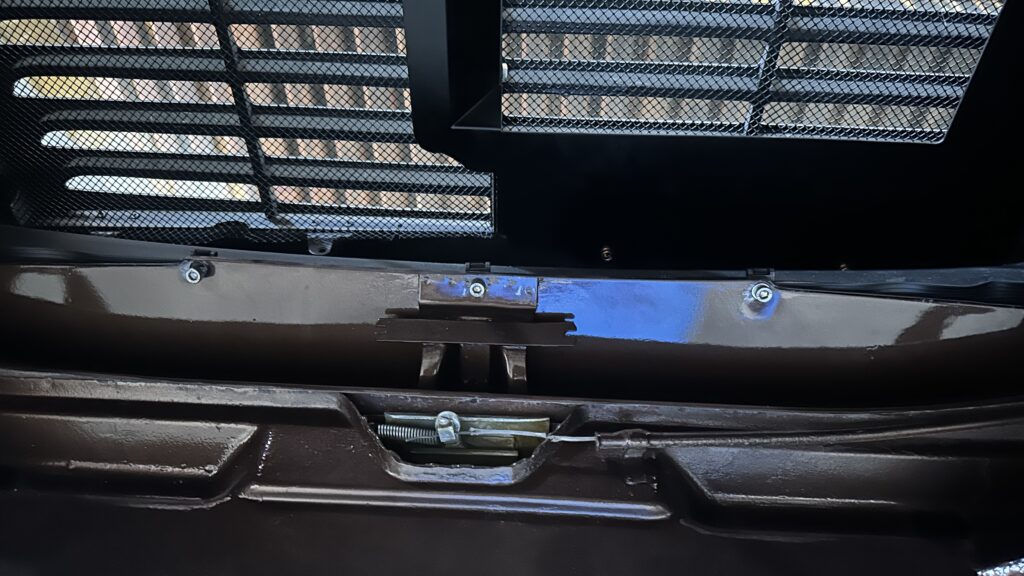

In these images, you can see the newly replaced fuel lines, both the main and return lines, routed and secured with the original-style clamps to maintain the authenticity and performance of the vehicle. Every component, from hoses to fittings, was carefully selected to ensure optimal fuel flow and reliability.

Rear Suspension Details

Suspension Rear Work – Full Overhaul and Zinc Coating

In this section, we highlight the extensive work done on the rear suspension of the Porsche 930. Every part was completely disassembled, inspected, and meticulously reassembled.

The bushings of the control arms and the stabilizer bar rubber components were replaced with high-quality OEM parts to ensure superior handling and durability. Additionally, the torsion axle rubber components were also replaced to improve the overall performance and smoothness of the suspension system.

To prevent corrosion and extend the lifespan of these critical components, all metal pieces were zinc-coated. This coating not only protects the parts from rust but also enhances their durability and resistance to harsh conditions.

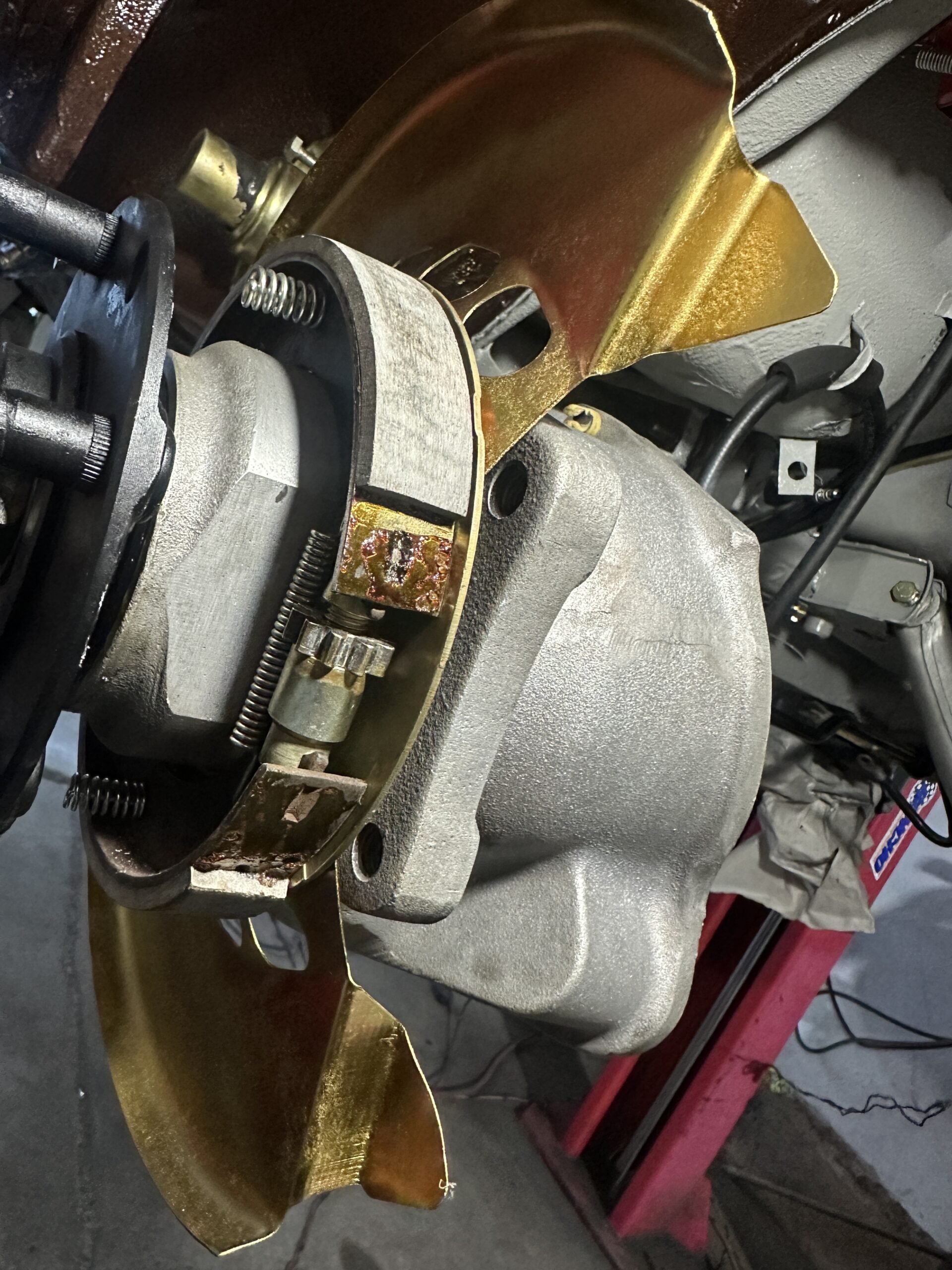

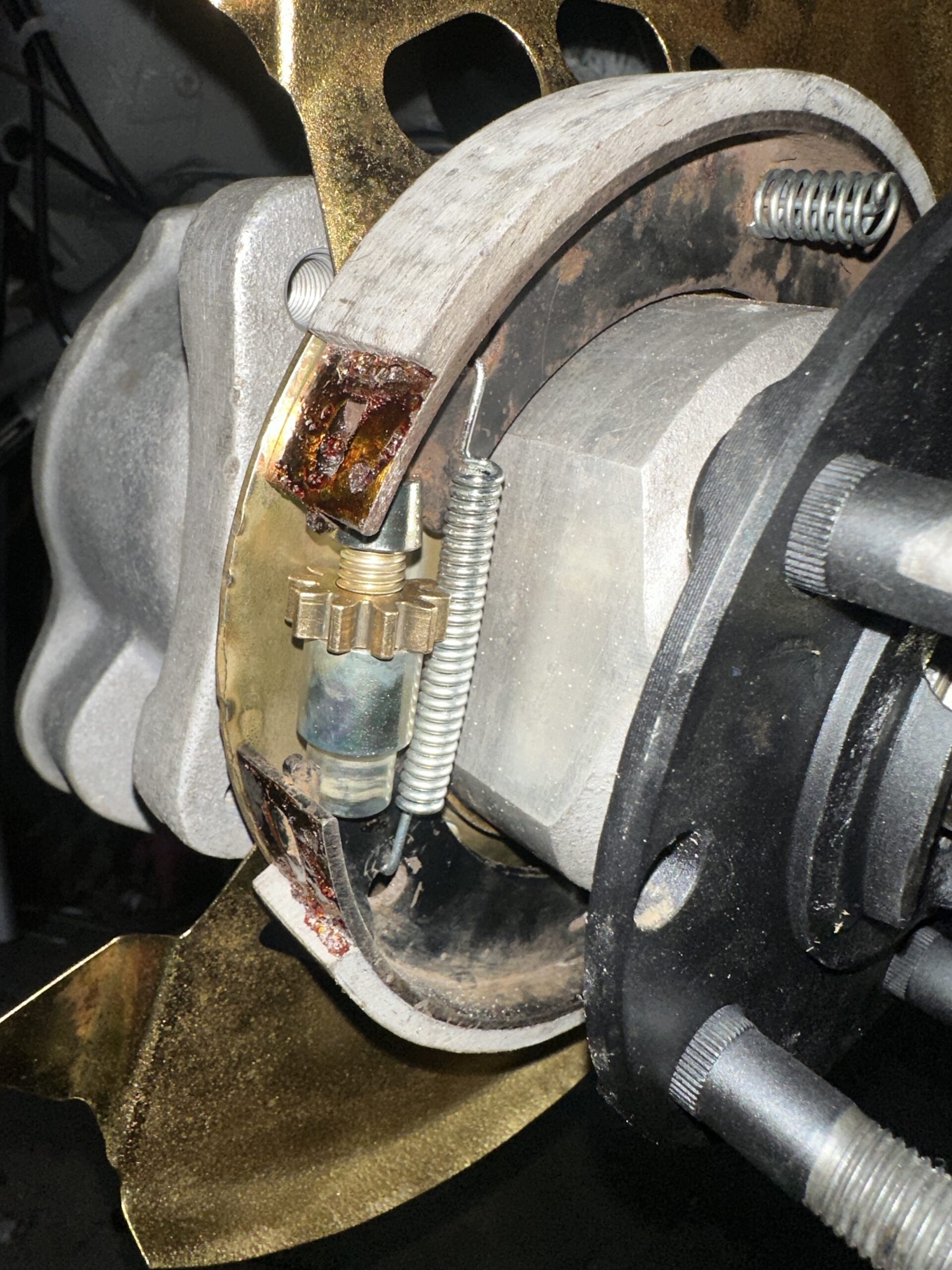

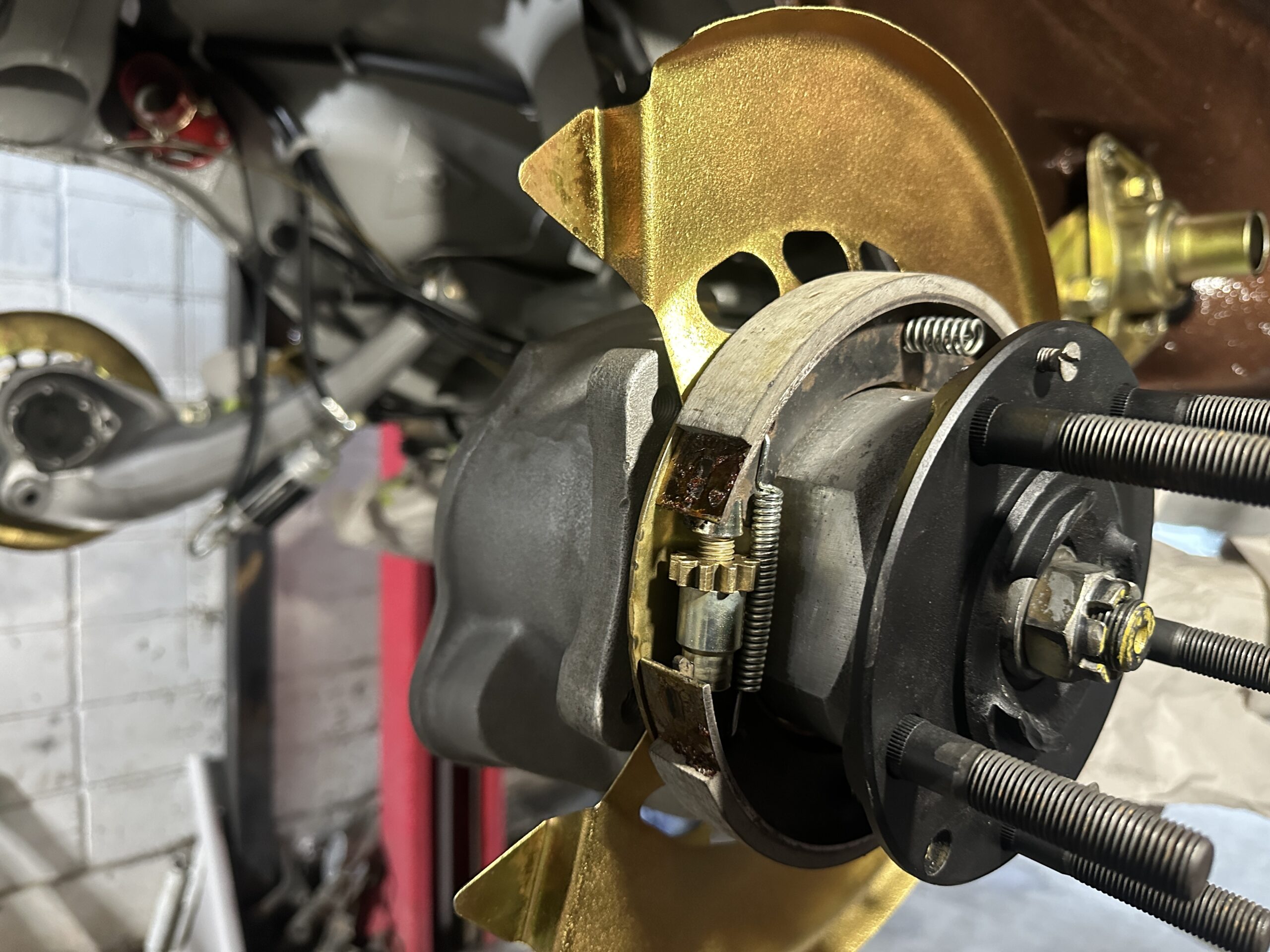

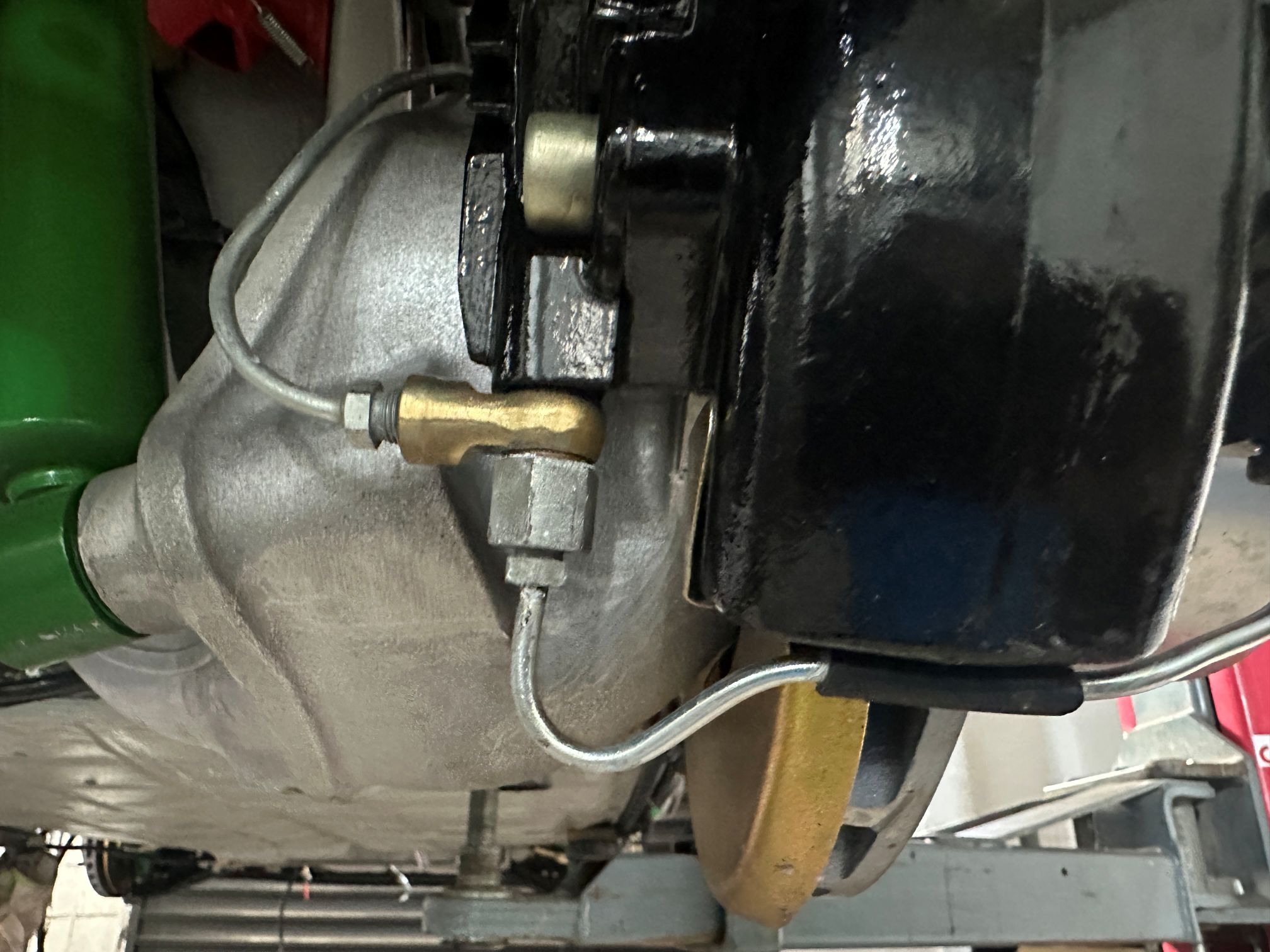

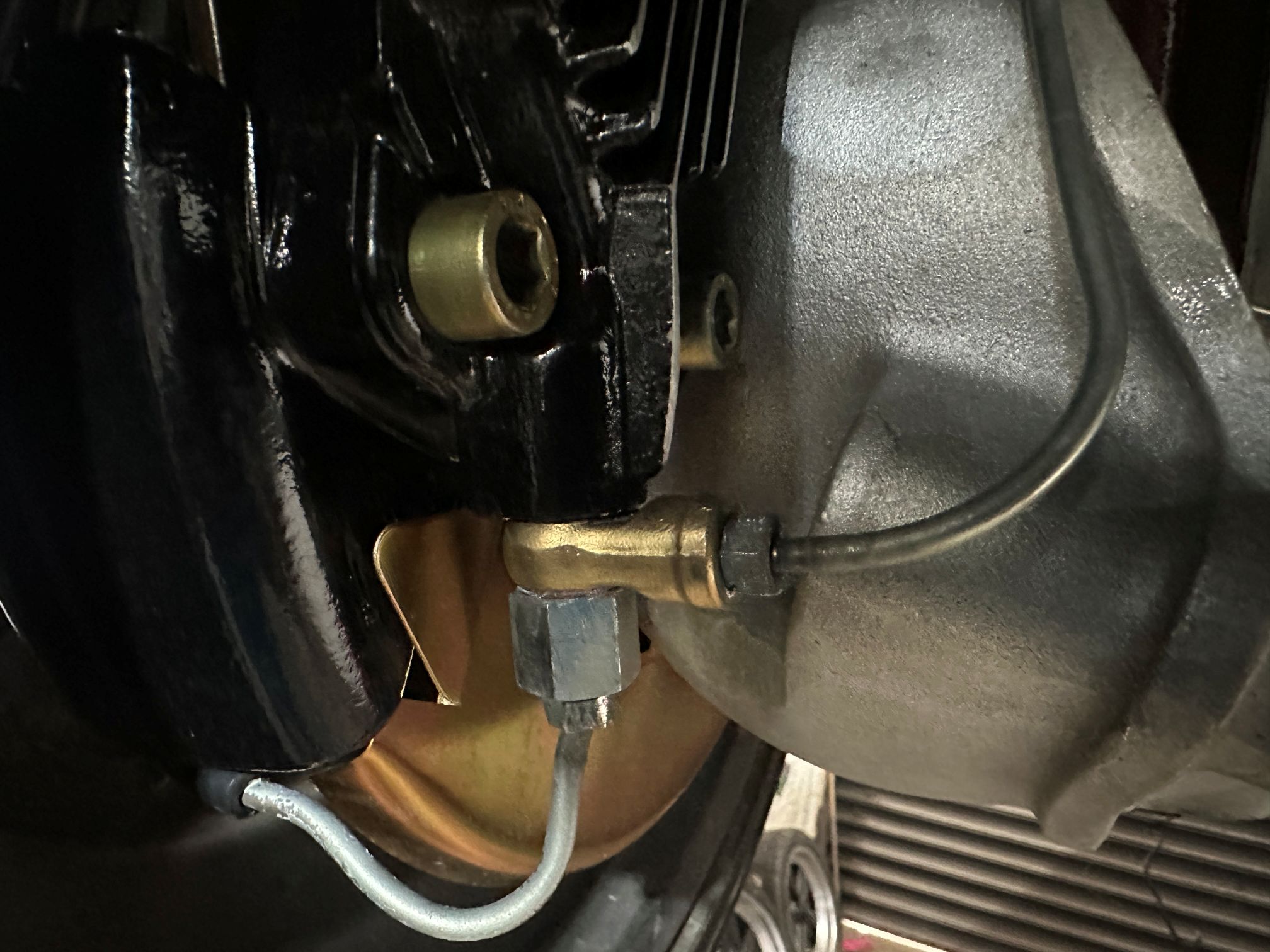

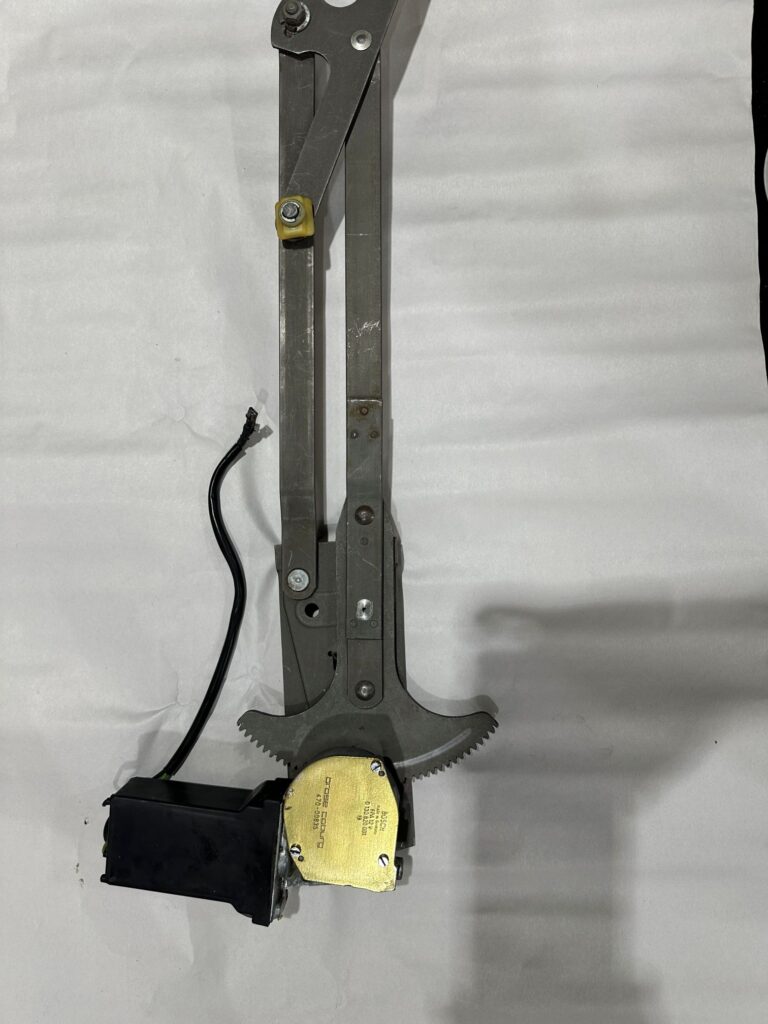

Complete Brake Overhaul System From Pedal to Caliper

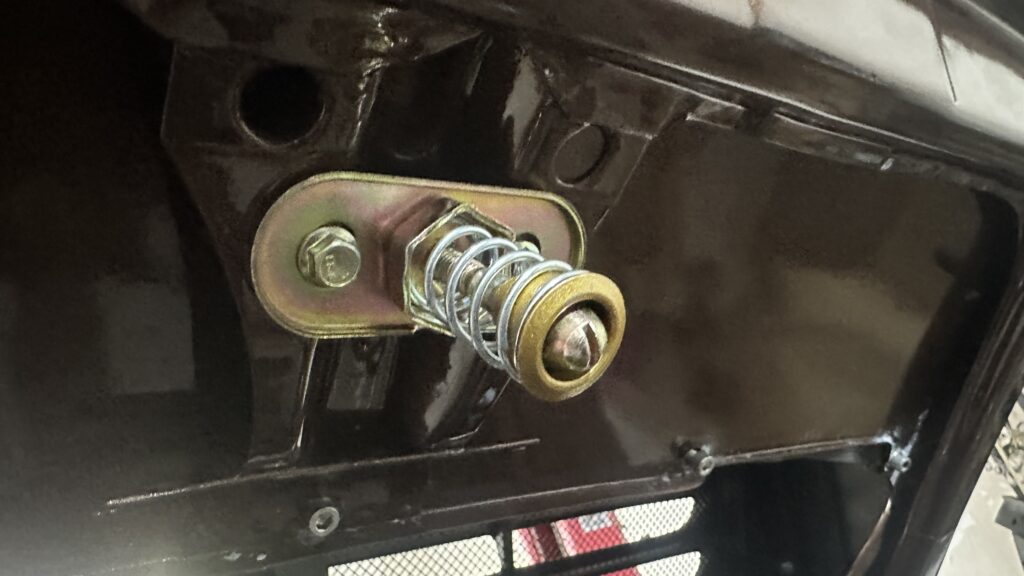

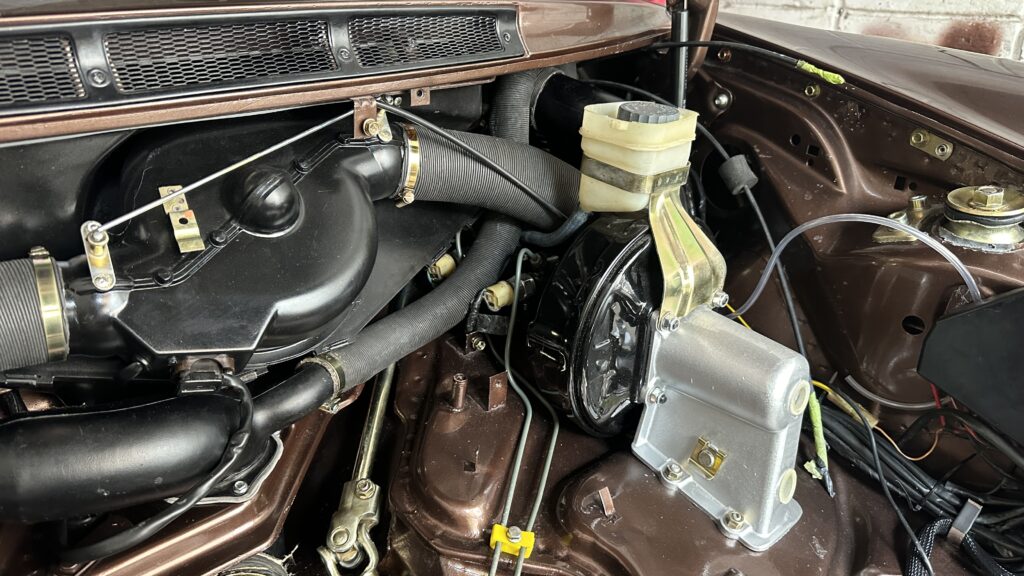

The brake system of this Porsche 930 underwent an extensive restoration. We began with the pedal assembly, replacing all the bushings, powder coating the pedal, and zinc-coating the brackets and springs. Additionally, the accelerator pedal was replaced to complete the setup.

The master cylinder was fully rebuilt and also received powder coating for durability. The brake booster was thoroughly inspected, and after testing its vacuum function, we confirmed it was in excellent condition. It was then refinished with new paint.

The hard brake lines were pressure-tested for integrity, and the front right brake line was replaced due to a damaged fitting and a bend caused by improper handling in the past. All four flexible brake hoses were replaced with new ones. The clamps between the hard and flexible lines were zinc-coated, and a new rear brake line was installed, which the vehicle previously lacked.

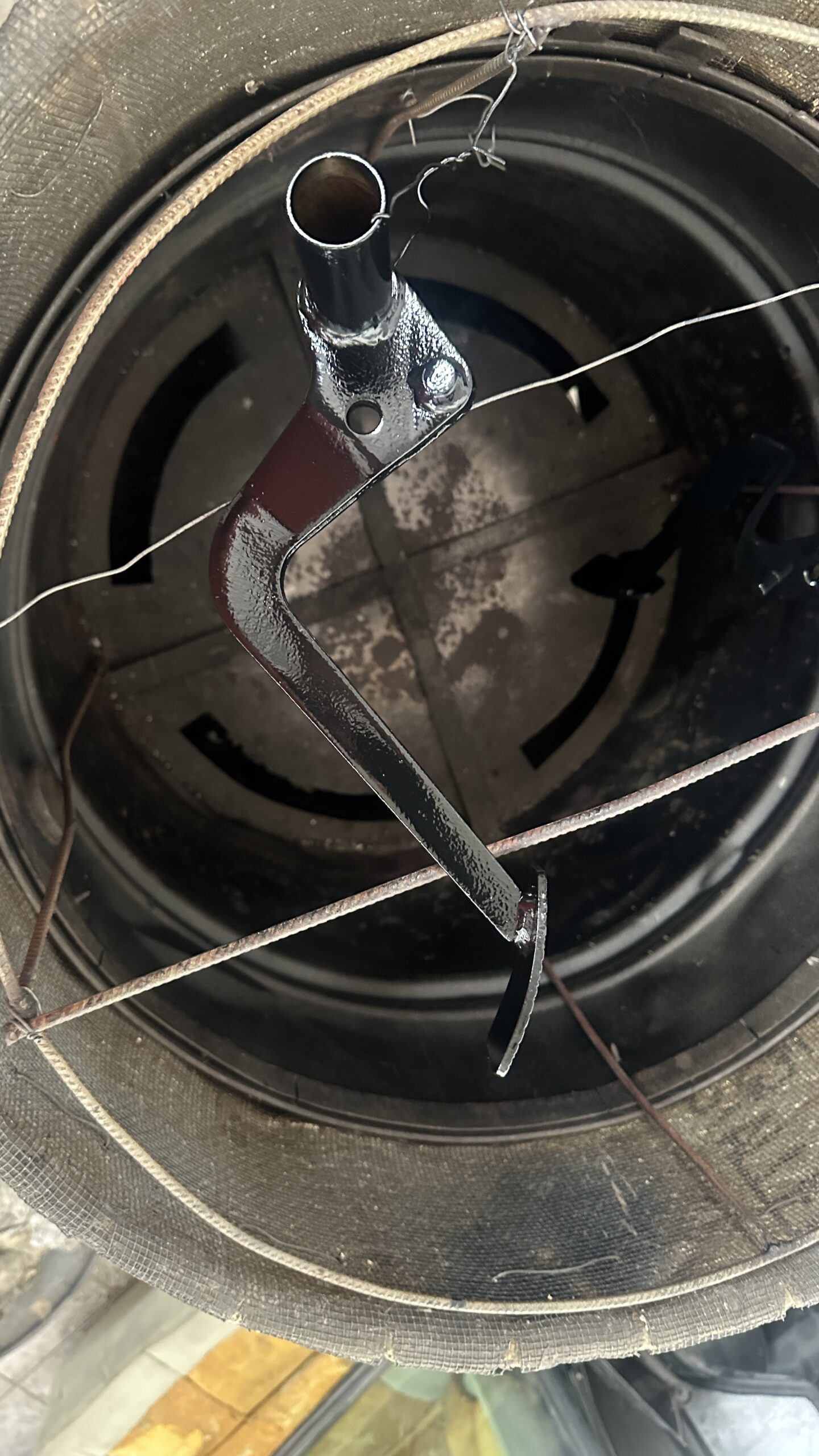

The brake discs were resurfaced to provide a perfect, smooth surface and are well above the minimum thickness specification. The front and rear brake pads were replaced with high-quality new pads. The handbrake shoes were also renewed.

Every piece of hardware related to the braking system was zinc-coated or chrome-plated, including the handbrake springs and dust boots, to provide a durable and aesthetically pleasing finish. The calipers were fully reconditioned and powder-coated with chrome-plated retention springs and brake bleeders.

The handbrake cables were inspected and found to be in perfect condition, so they were only zinc-coated to match the rest of the components.

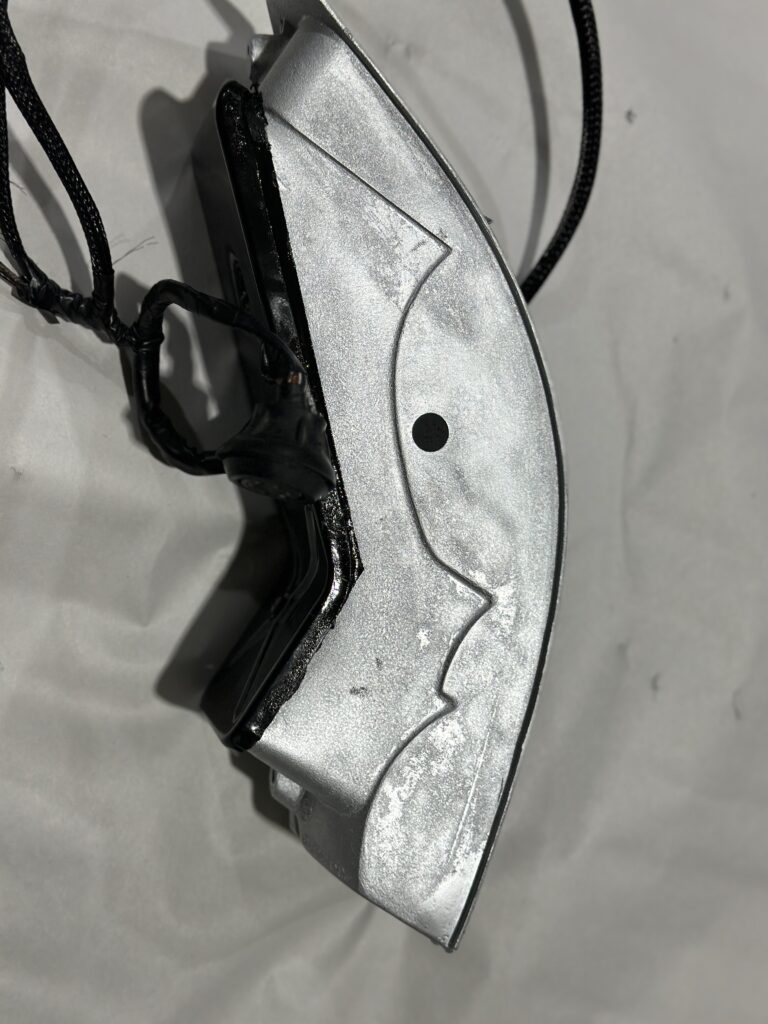

Steering System Overhaul

Steering System Restoration:

The steering system was thoroughly inspected, from the steering wheel to the wheel terminals. The tie rods were checked and found to be in excellent condition, as the previous owner had replaced them. The steering rack boots were replaced with new ones. The outer tie rod terminals received a zinc treatment for added durability. The tie rods were powder-coated for a clean and durable finish. The steering rack was disassembled, cleaned, and lubricated. The steering column was zinc-coated, and a new bushing was installed. The clamps on the column were also zinc-coated, ensuring everything is in perfect working condition and fully secure.

The sway bar bushings were replaced with new ones, ensuring better stability and control. The clamps were zinc-coated for added protection against corrosion. Additionally, the sway bar received a fresh coat of powder coat paint, giving it a durable and attractive finish.

Rod Bearing Inspection and Maintenance

The front rod bearings were replaced with new, high-quality German-made bearings, ensuring superior performance and durability. In addition, new seals were installed to guarantee a perfect seal and prevent any leaks. The rear rod bearings were thoroughly cleaned, lubricated, and received new seals, as they were still in excellent condition and required only minor maintenance to maintain their functionality.

In the images, you can see the old seals and bearings still mounted on the hub, with the new bearings and seals laid out on the table.

Shock Absorber Inspection and Maintenance:

During this part of the restoration, the shock absorbers were thoroughly inspected. The bushings were replaced, and the absorbers were repainted, as they were found to be in perfect condition. There were no leaks or damage of any kind, ensuring optimal performance for the suspension system.

Air Conditioning and Heating System

In this part of the restoration, we addressed a very critical aspect in all 911 and 930 models, especially regarding the A/C system, which has a reputation for being very inefficient from the factory. Our goal was to improve the system without being too invasive, so the originality of the 930 could be easily restored by any future owner who prefers to revert it to its original condition.

As mentioned earlier, the first step was to replace all the hoses, either due to age or the inefficiency of the old ones. The previous hoses were made of simple rubber both internally and externally. The most common cause of refrigerant leaks in these vehicles is undetectable due to the porosity of these hoses, which allow small leaks over time. This is why owners of these older Porsches must recharge their A/C system periodically. We replaced these with new barrier hoses that feature a hard silicone or plastic inner liner, effectively preventing leaks.

Another common issue with the Porsche A/C system is its low condensation capacity due to the placement of the condensers. One is located at the rear without any auxiliary fans, relying only on the engine cooling fan. However, despite the engine bay absorbing cool air from the outside, it was still difficult for the condenser to cool the refrigerant enough to reach the necessary subcooling temperatures, which are required to achieve proper liquid saturation.

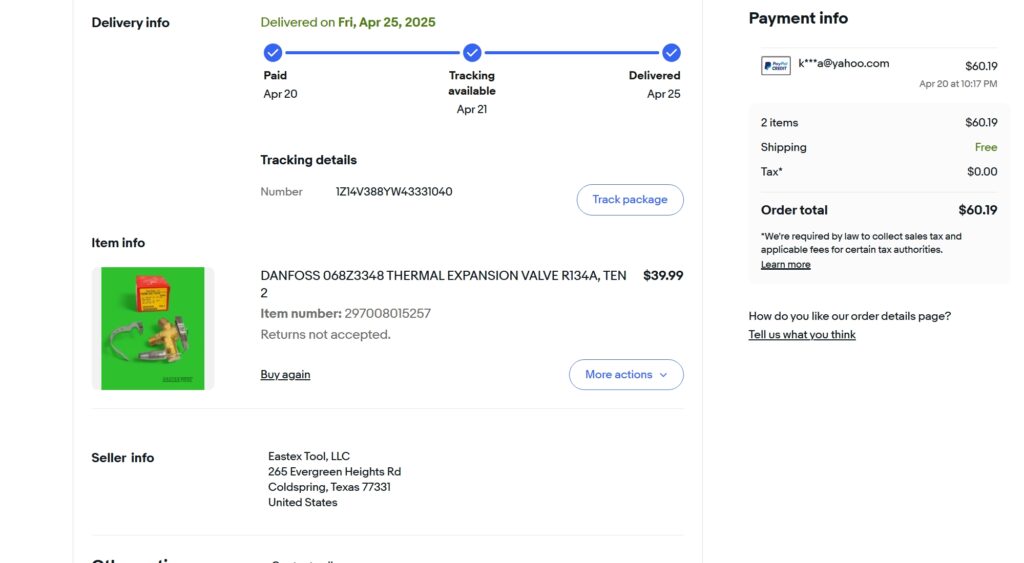

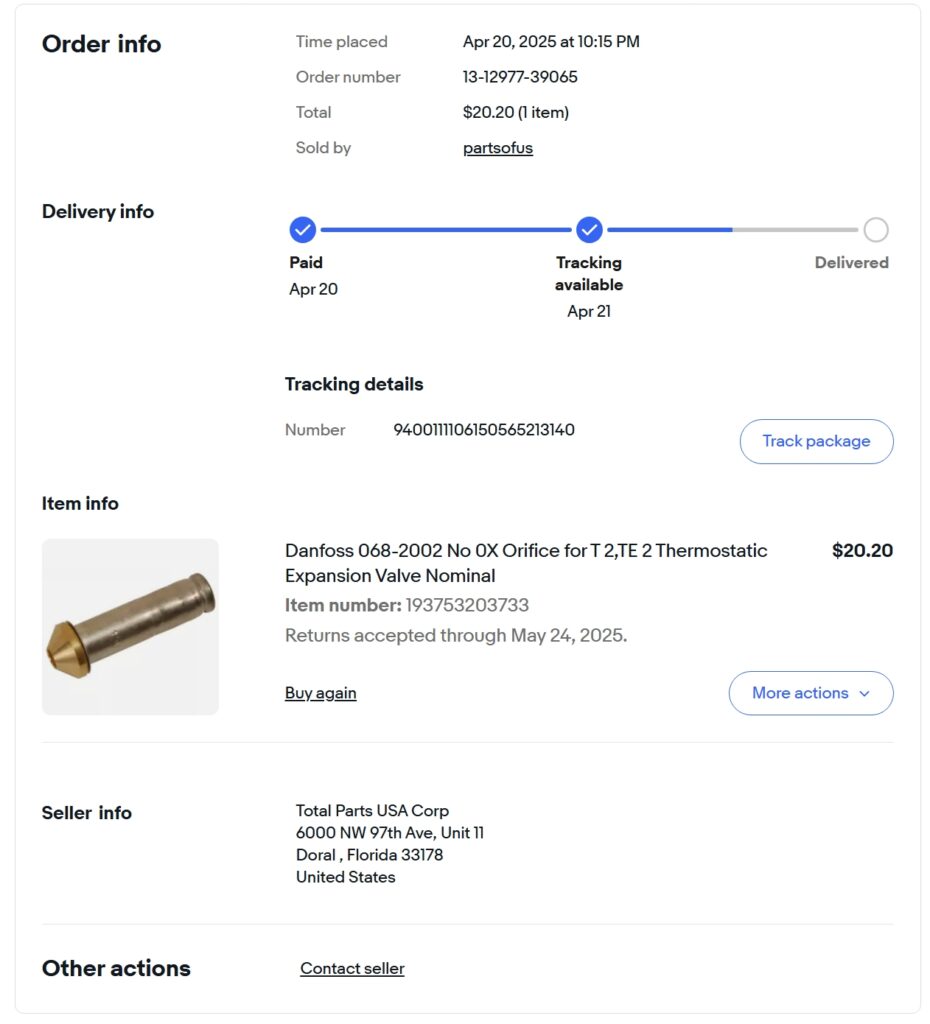

To solve this, we installed an additional 14×14-inch condenser at the rear left fender, assisted by an electrical fan. This significantly improved the refrigerant’s subcooling efficiency. We also added an adjustable expansion valve (TXV) from Danfoss to better control the pressure differential between the low and high sides, where the cooling effect occurs.

We carried out maintenance and cleaning of the front condenser, added a new rear condenser, and upgraded to a much more efficient 508 compressor, replacing the old York model. All flare-type connections with cooper shims were kept original, ensuring that if the new owner prefers to revert to the old system, it can easily be done. Although I doubt they will, given the great cooling performance now, but it’s up to each owner.

I’ve also kept the old York compressor and R12 valve for those who might want to return to the original system. Keep in mind that R134a is now used, and I recommend continuing with it if reverting back to the older system, as R12 is no longer available and is banned. The TXV has been updated for R134a compatibility.

Additionally, a central vent grille was added to improve air circulation, though it can be reverted to its original state with just two screws. We also performed thermal insulation in the ceiling and floor of the car. I decided not to add it to the doors, as it could change the sound quality (especially for anyone testing the car by tapping to check for body filler). The insulation was done as efficiently as possible, ensuring optimal performance.

Lastly, the heating hoses were replaced with new ones, and the original clamps were restored. We also added discrete rubber seals at the internal joints to prevent any leakage. The rear flaper heating ducts were restored and powder-coated in red the original color , the spring was chromed, and the bolts were zinc-coated. New seals and cables were installed, and the automatic heating system was cleaned, restored, and is now functioning as if it just left the dealership.

Now, even when temperatures outside hit 90°F or higher, you’ll enjoy a perfect internal climate. No more worrying about the inefficiency that the factory A/C systems were known for. Whether it’s a hot summer day or a long drive, you’ll feel cool and relaxed inside, no matter the heat outside. The system now ensures that you’re always comfortable, making every ride more enjoyable.

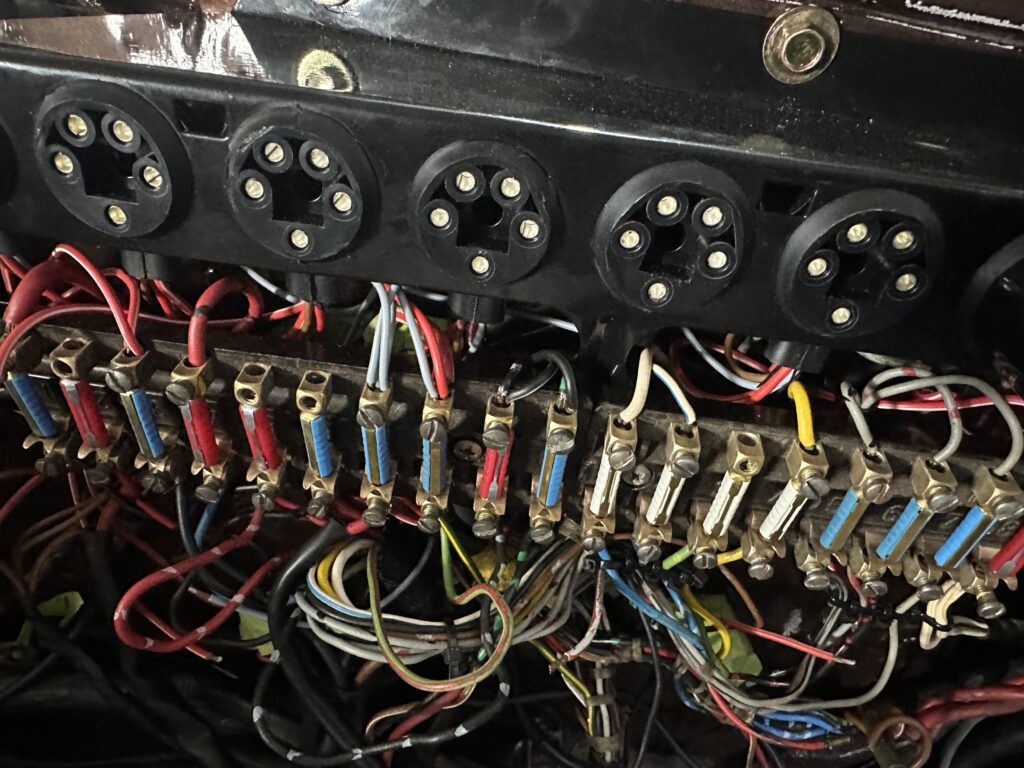

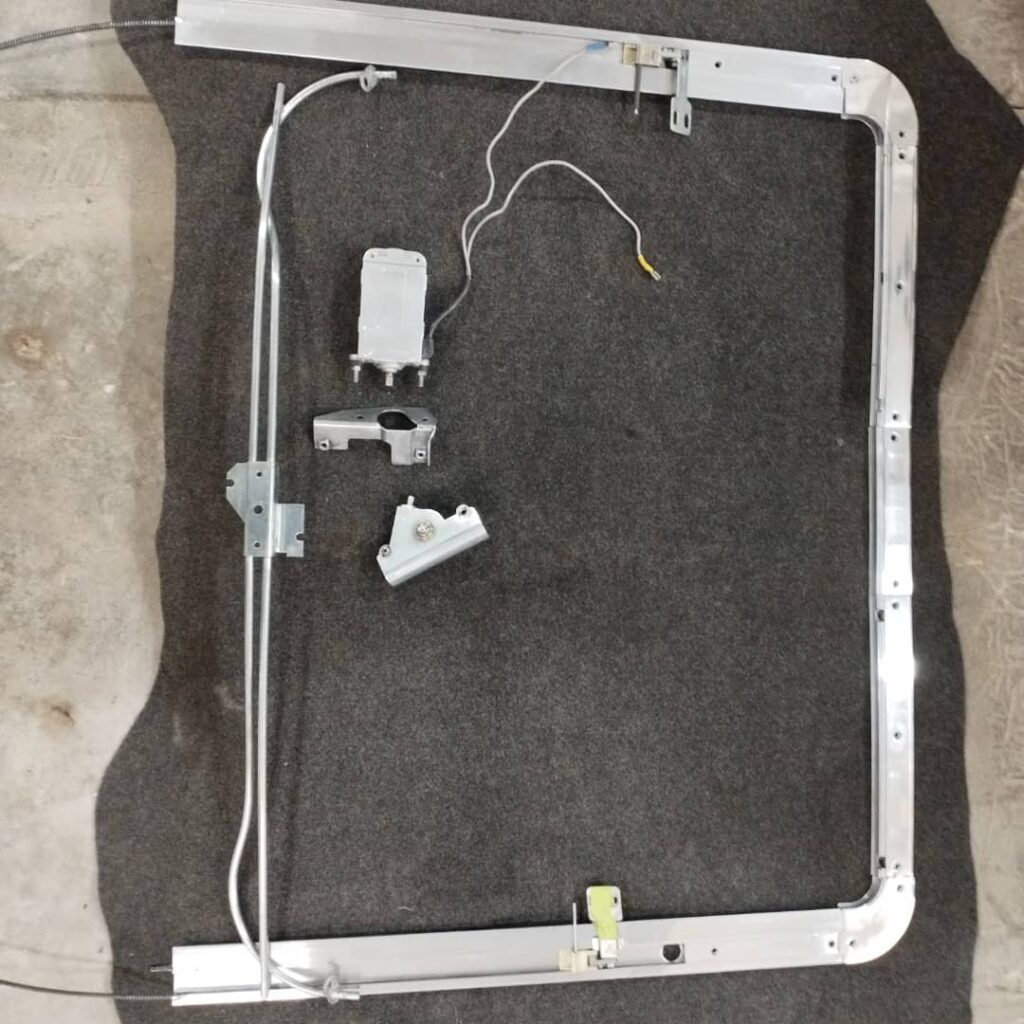

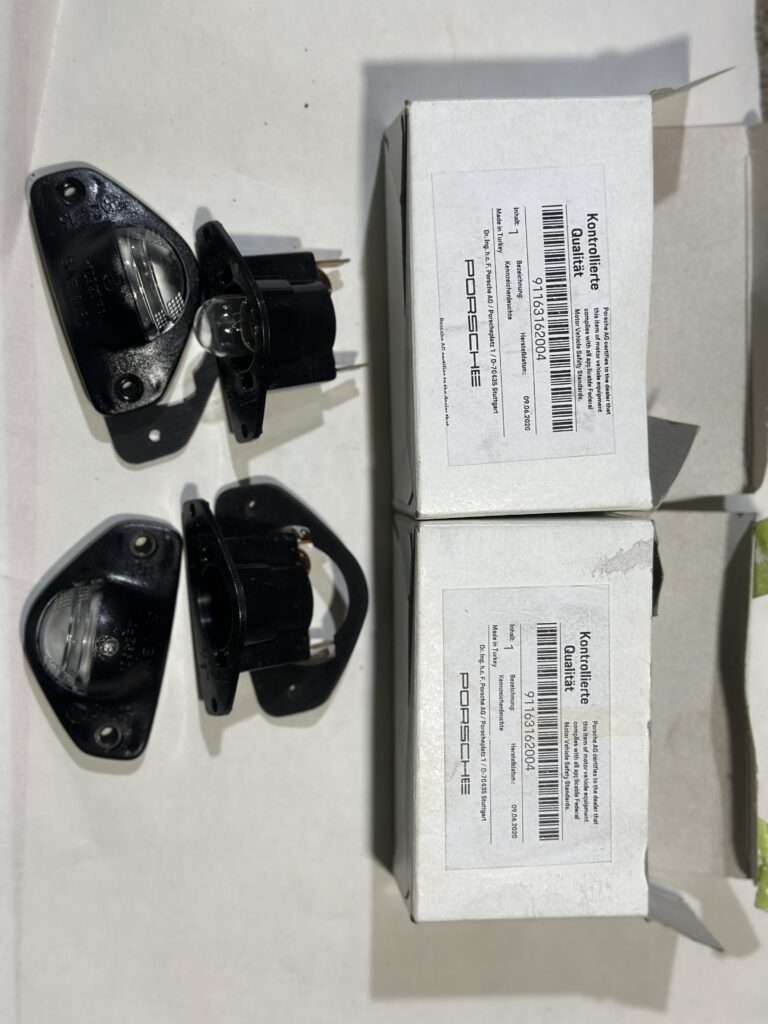

Electrical System

The entire electrical system was removed from the vehicle, thoroughly tested, and reinstalled with original wiring. This included the headlamp washer system, window washer system, and fuel pumps, which are often the most affected by age.

All relays were replaced with new ones to ensure reliability and performance.

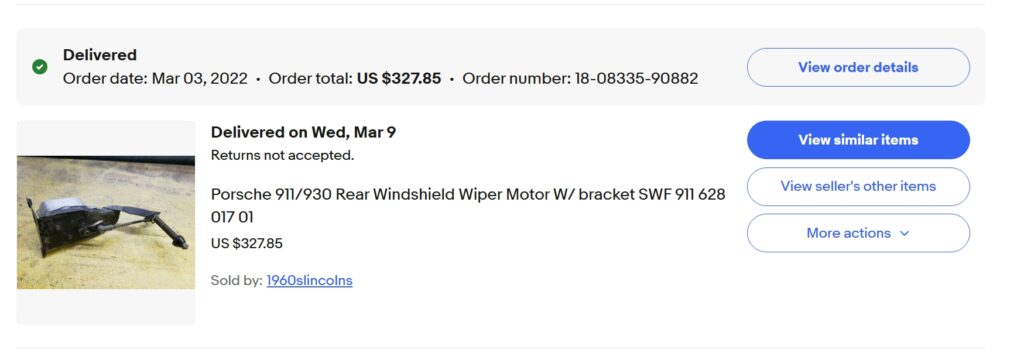

The rear windshield washer switch was replaced with a new one, and the window washer switch was also upgraded to a new component.

The horns were restored to their original functionality.

The windshield washer reservoir and headlamp washer reservoir were replaced with OEM parts, along with all new hoses and both water pumps to ensure proper fluid circulation.

In addition, many more components were inspected, restored, or replaced to maintain the system’s integrity and ensure long-term performance.

Interior

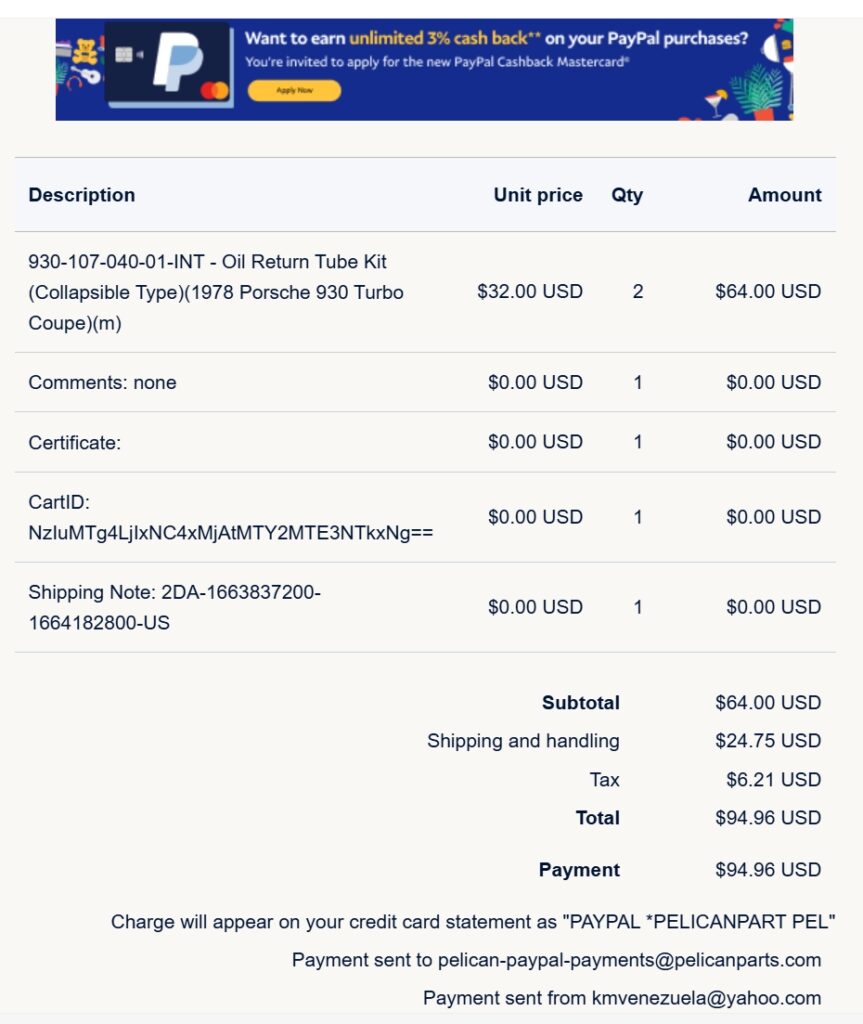

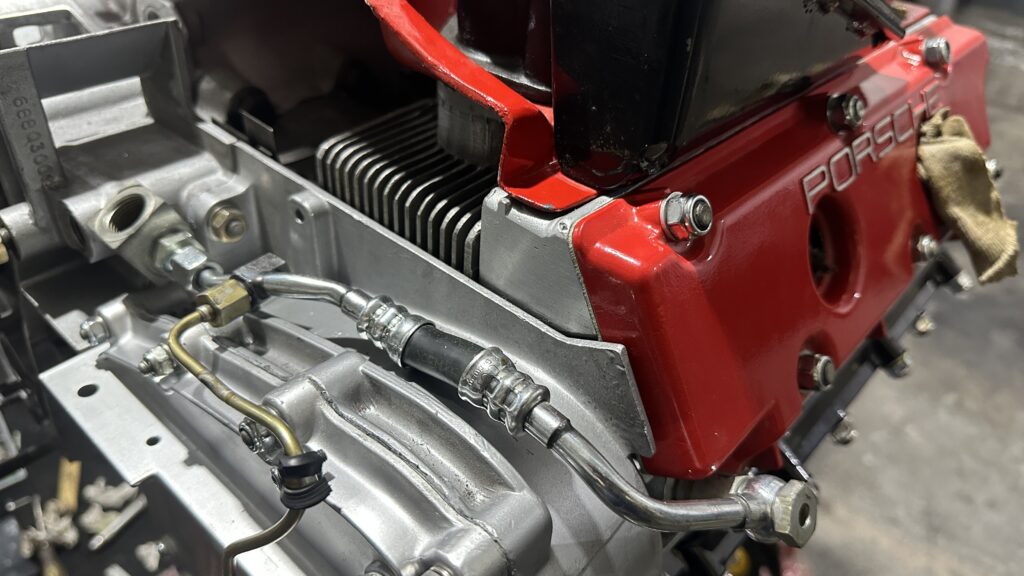

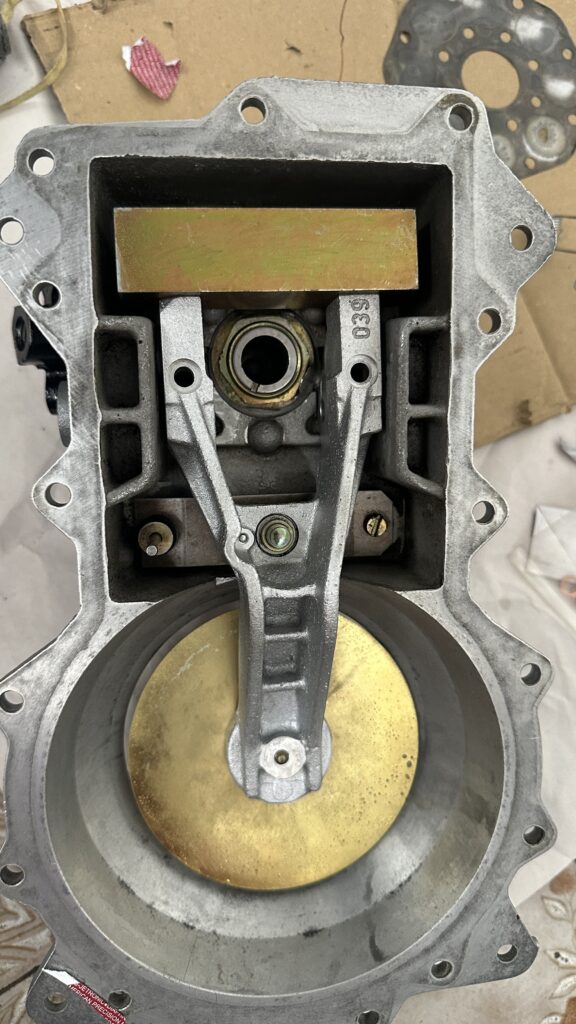

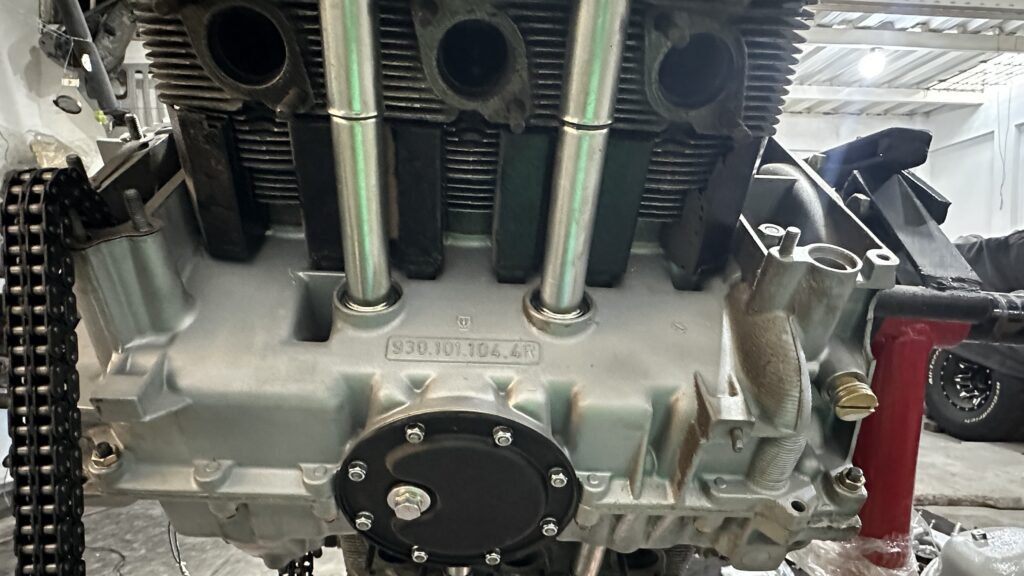

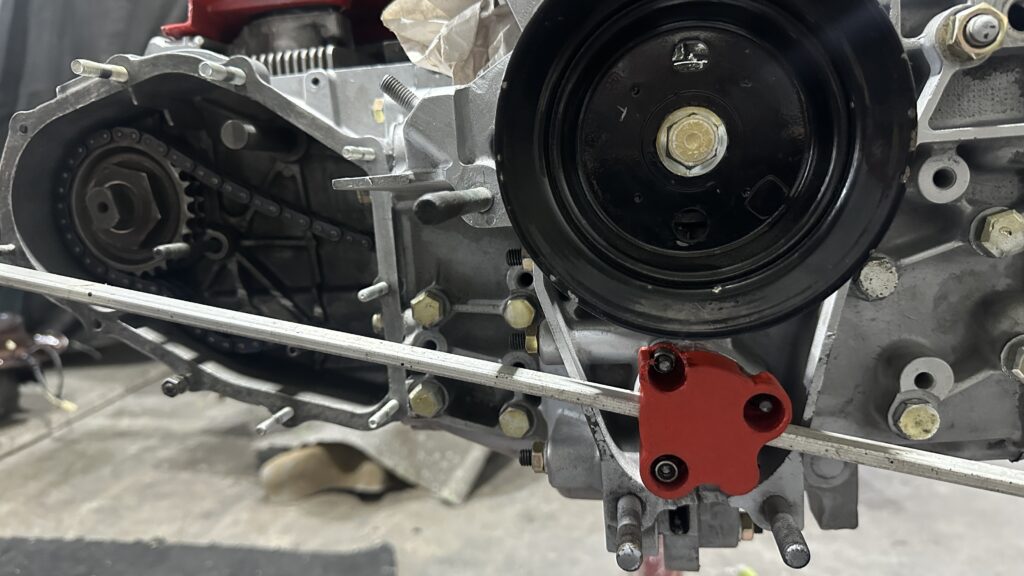

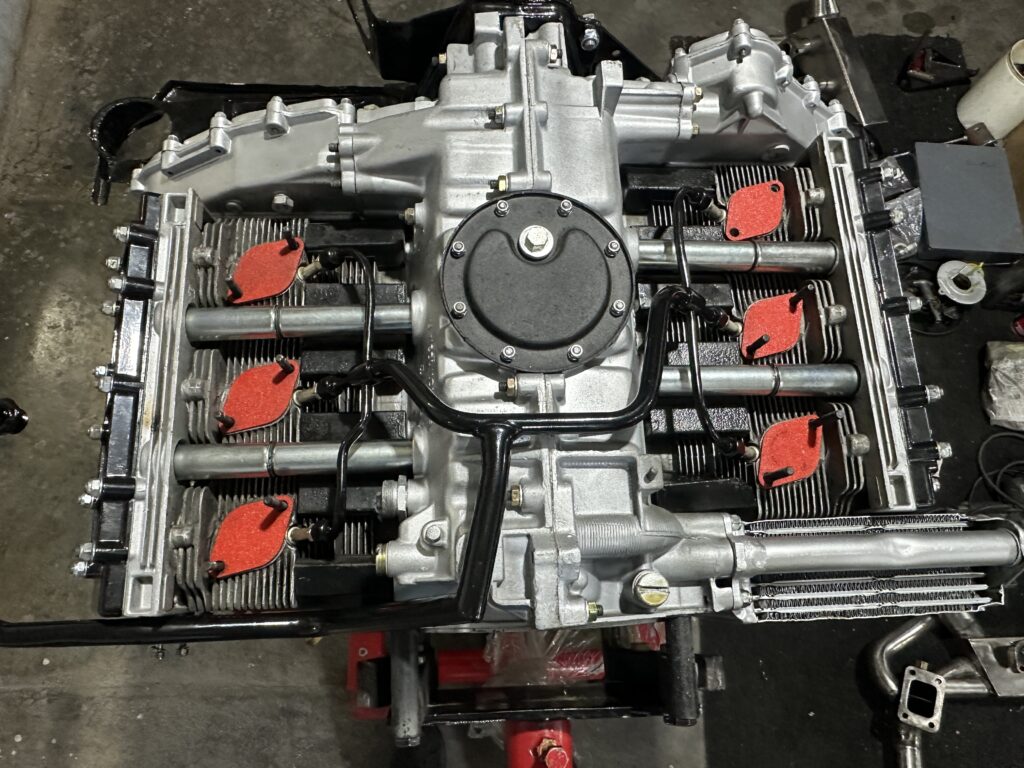

Engine Overhaul

Engine Overhaul

In this section, you’ll see part of the engine overhaul process. Unfortunately, since this project started about two years ago, I didn’t initially plan to document every step, so by the time I decided to create this page, the long block had already been assembled.

That said, it’s important to note that this engine was fully rebuilt, with all internal components replaced, including bearings, piston rings, and everything necessary to bring it back to optimal condition.

At the end of this section, under invoices and receipts, you’ll find proof of purchase for all components used during the rebuild.

In this video, we show the cam timing setup at 0.028 inches, which corresponds to approximately 0.71 mm.

The manufacturer’s recommended range is between 0.65 mm and 0.80 mm, placing this setting well within spec. Accurate timing within this range ensures proper valve overlap and optimal engine performance, particularly under boost.

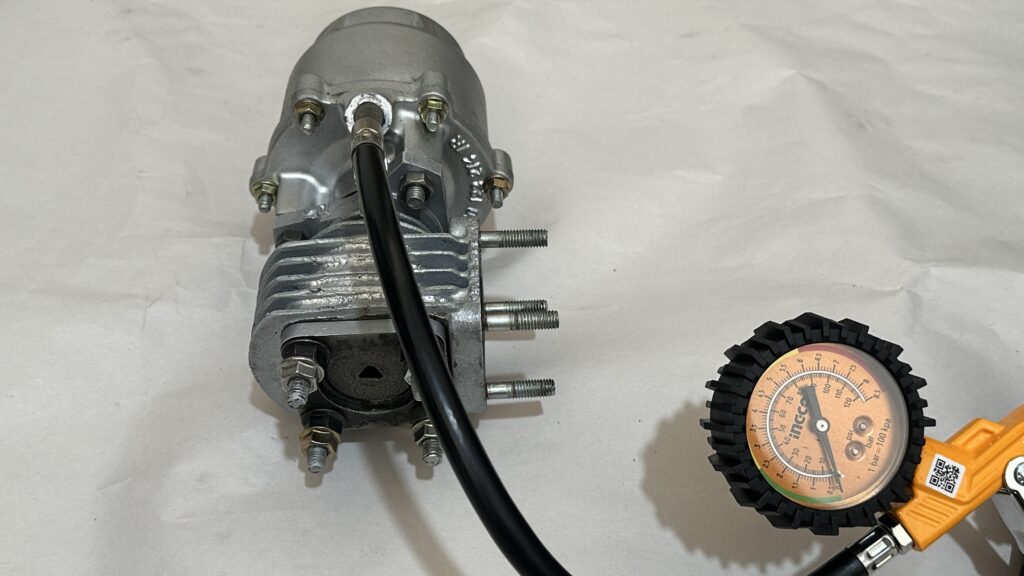

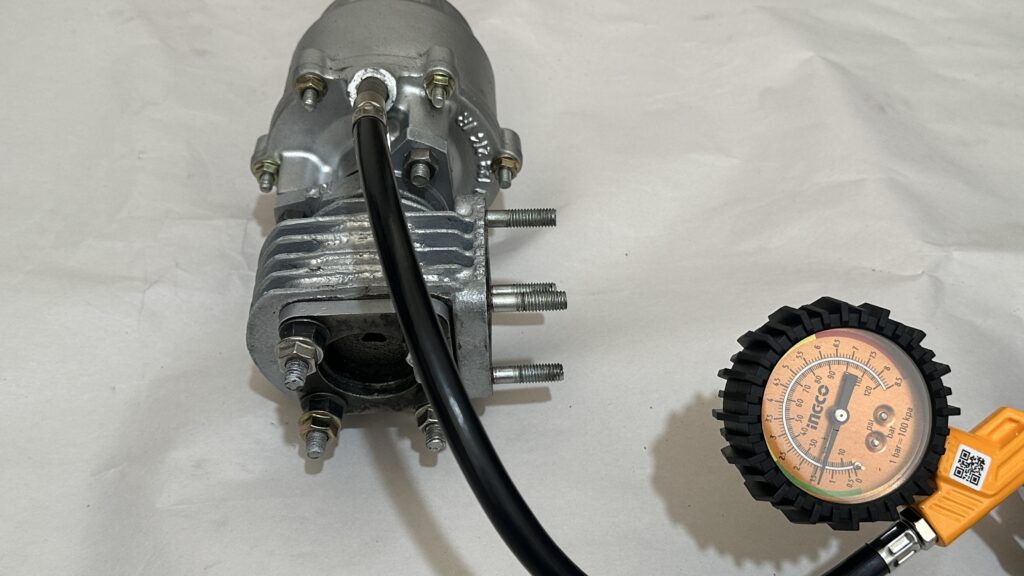

Turbo System Rebuild

This video demonstrates the wastegate operation described in the previous images.

It visually confirms the valve remains fully closed at 0 bar, begins to open gradually at approximately 1.1 bar, and reaches full opening at 1.4 bar. This behavior is essential for efficient boost control, allowing the turbocharger to perform optimally while protecting the engine from excessive pressure.

Oil Cooler System

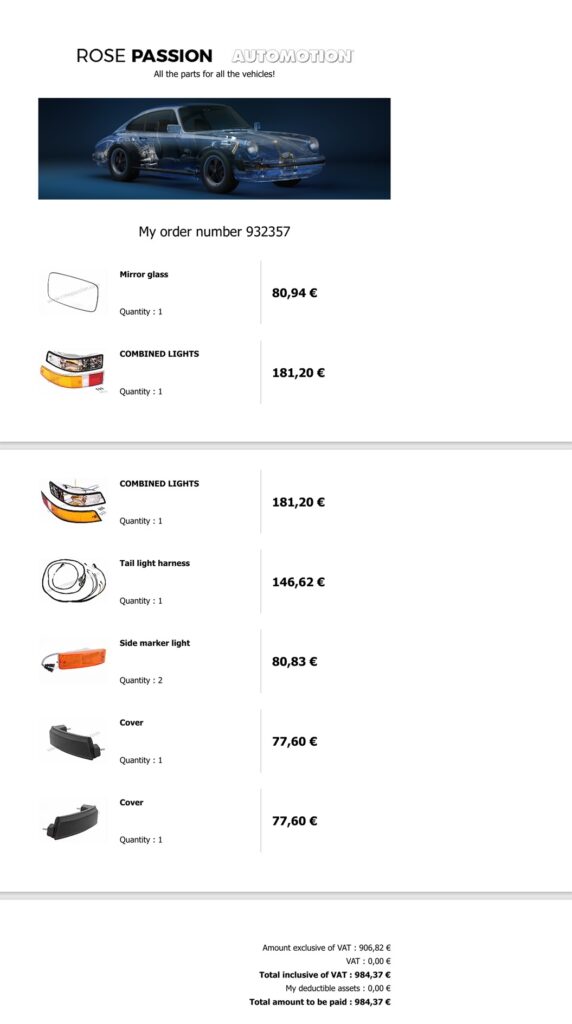

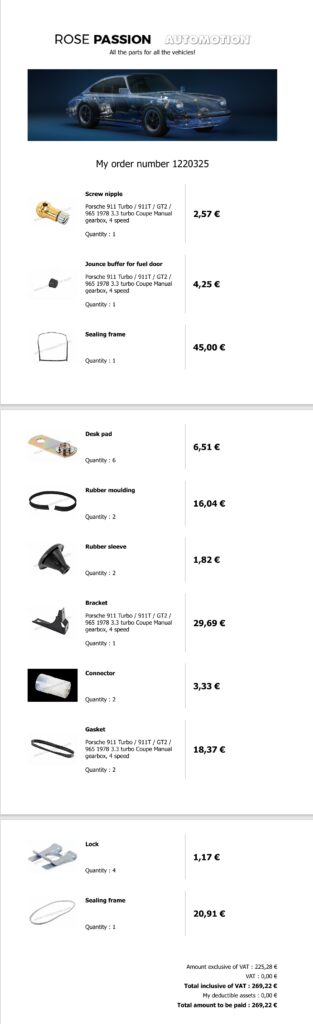

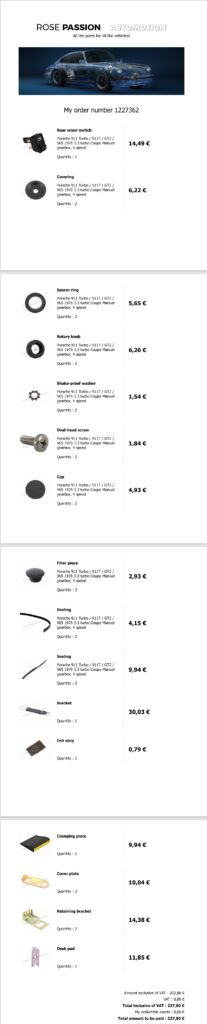

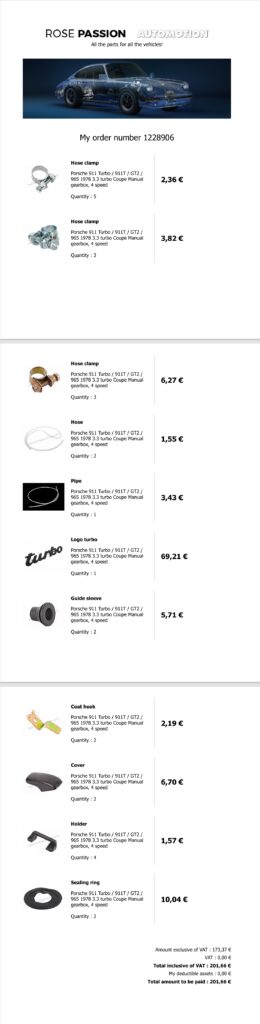

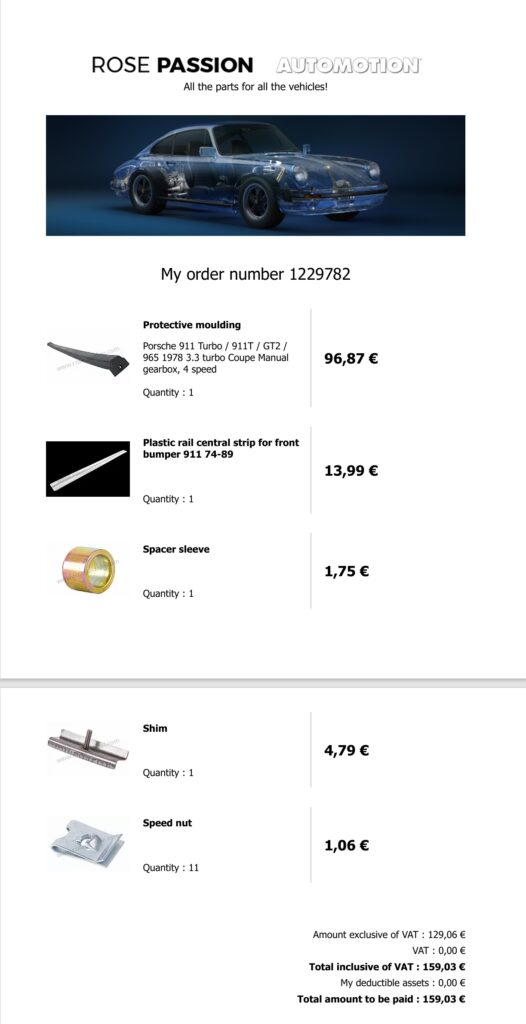

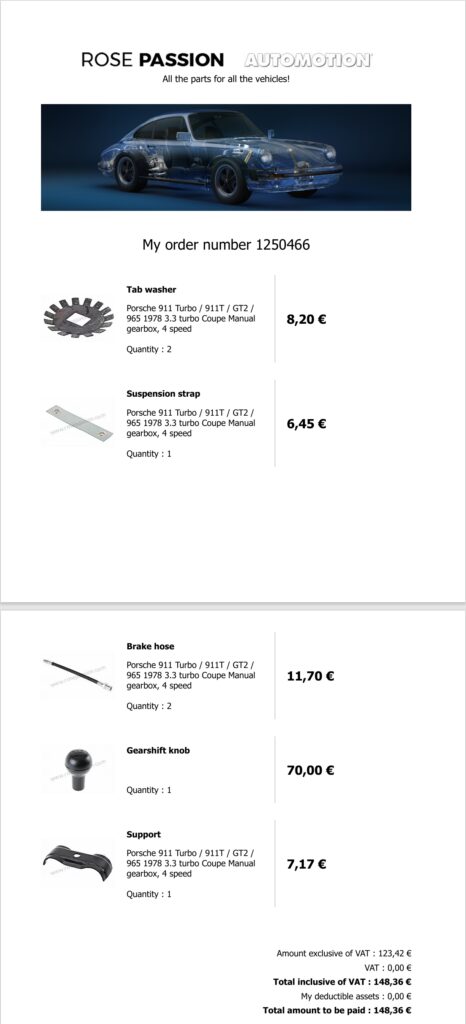

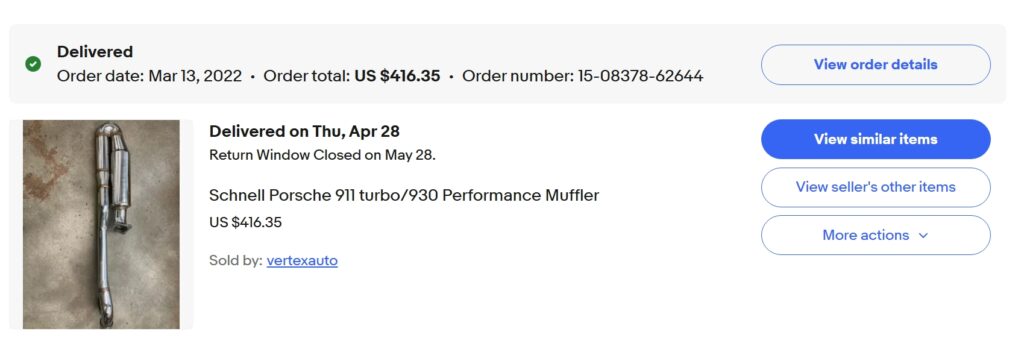

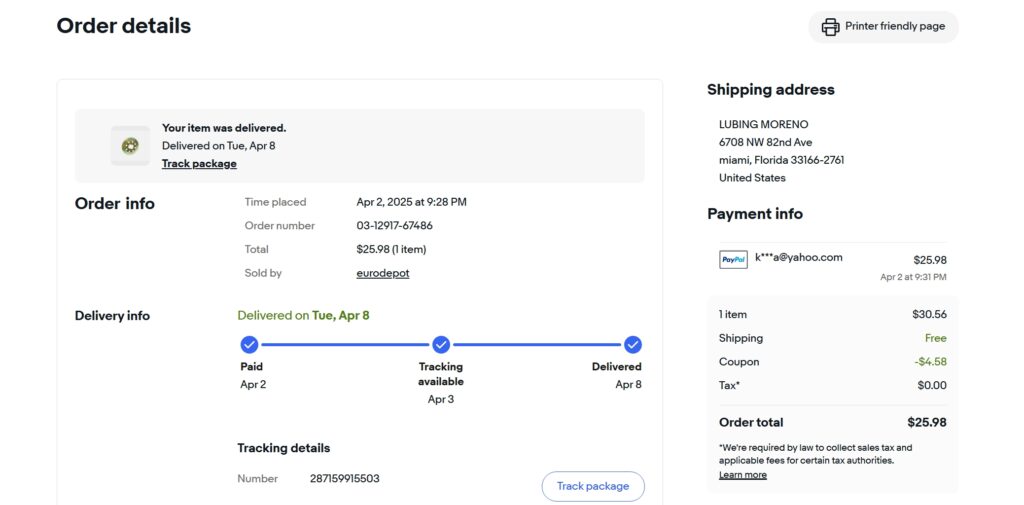

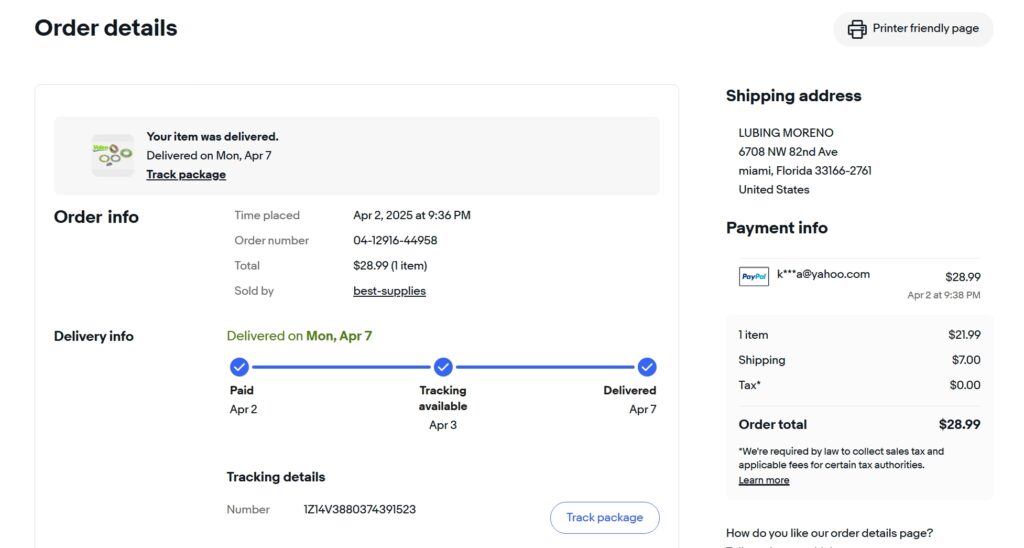

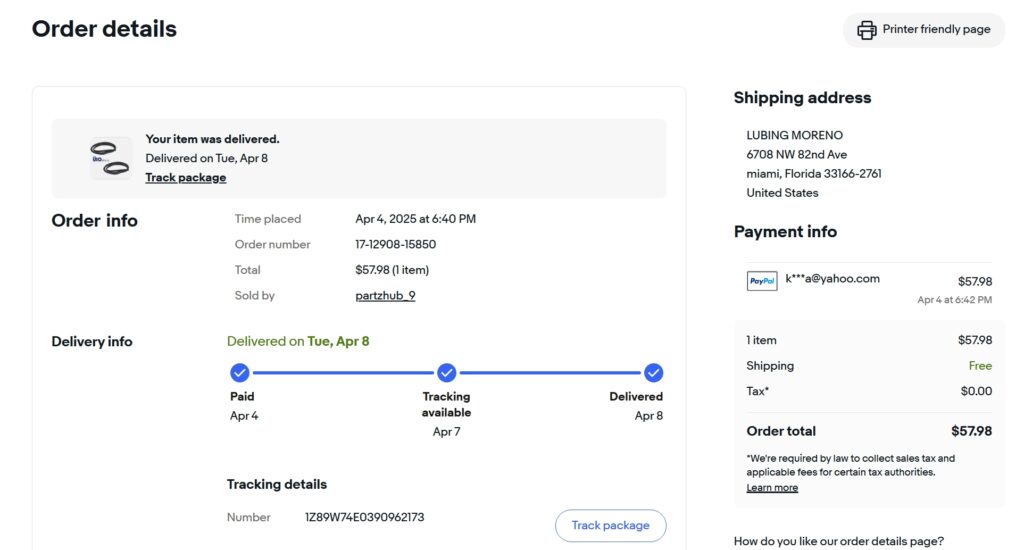

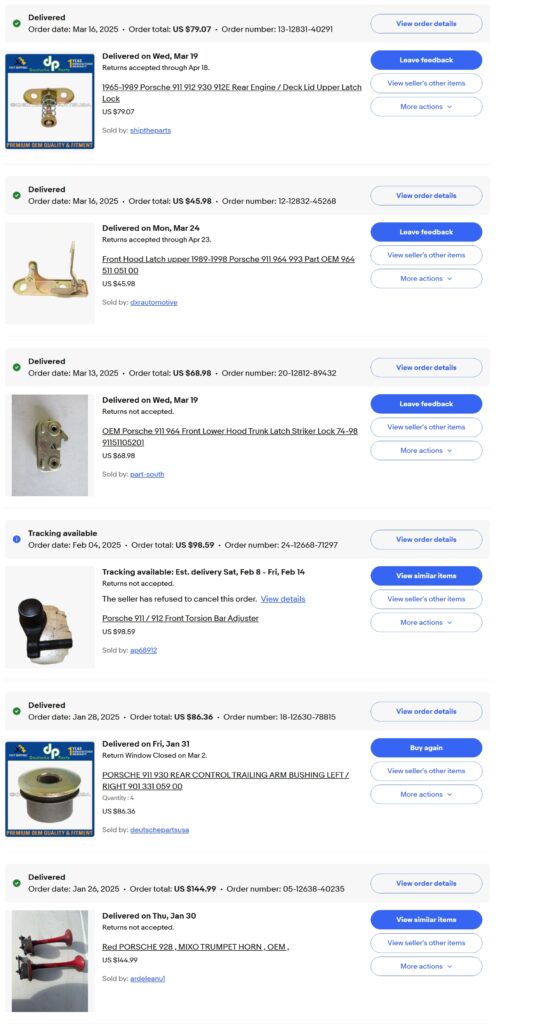

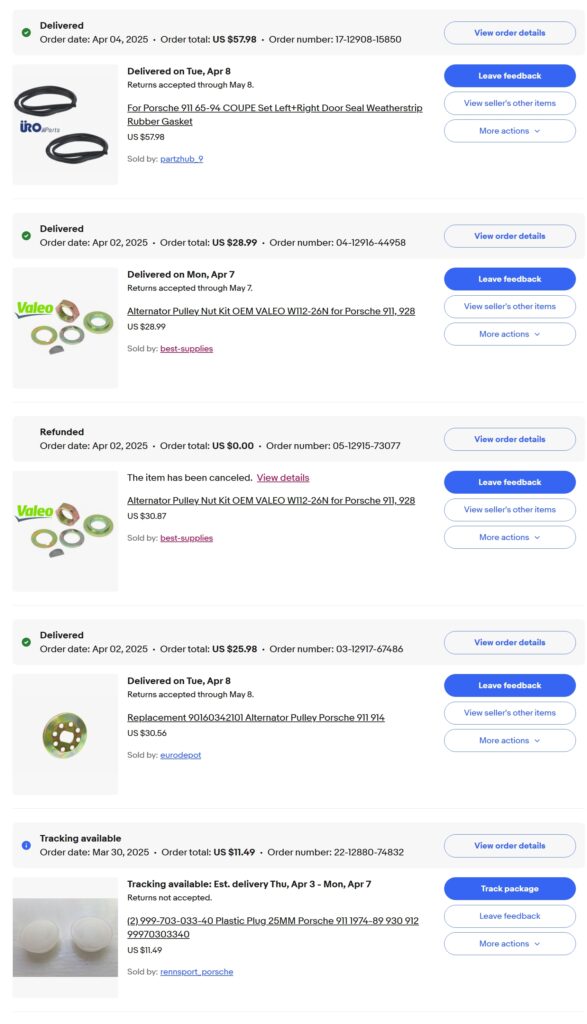

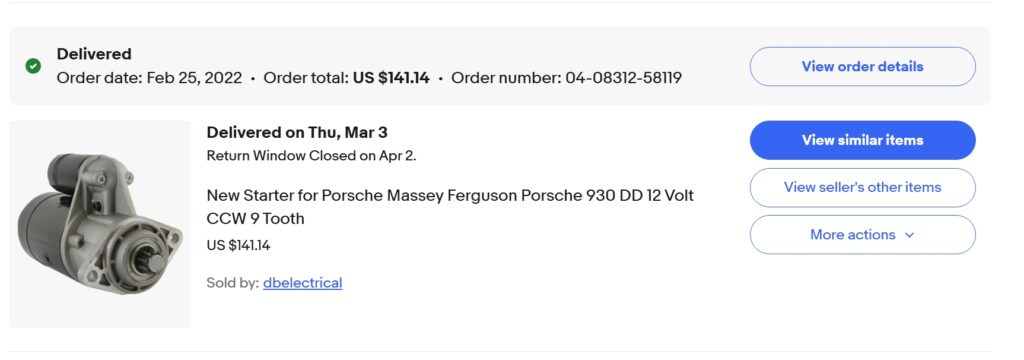

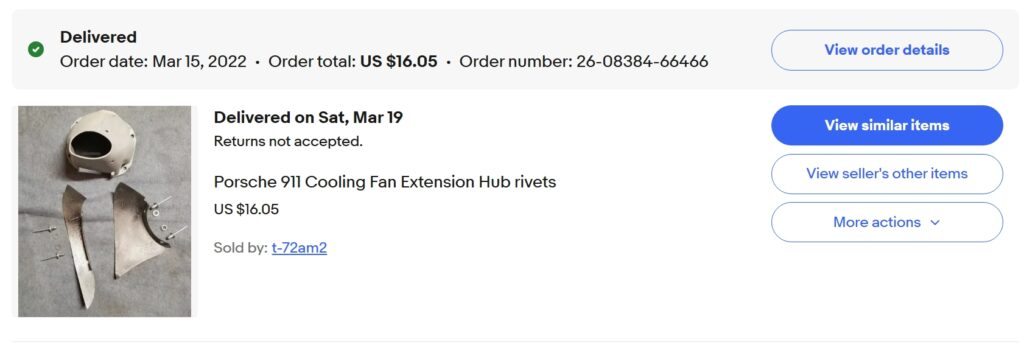

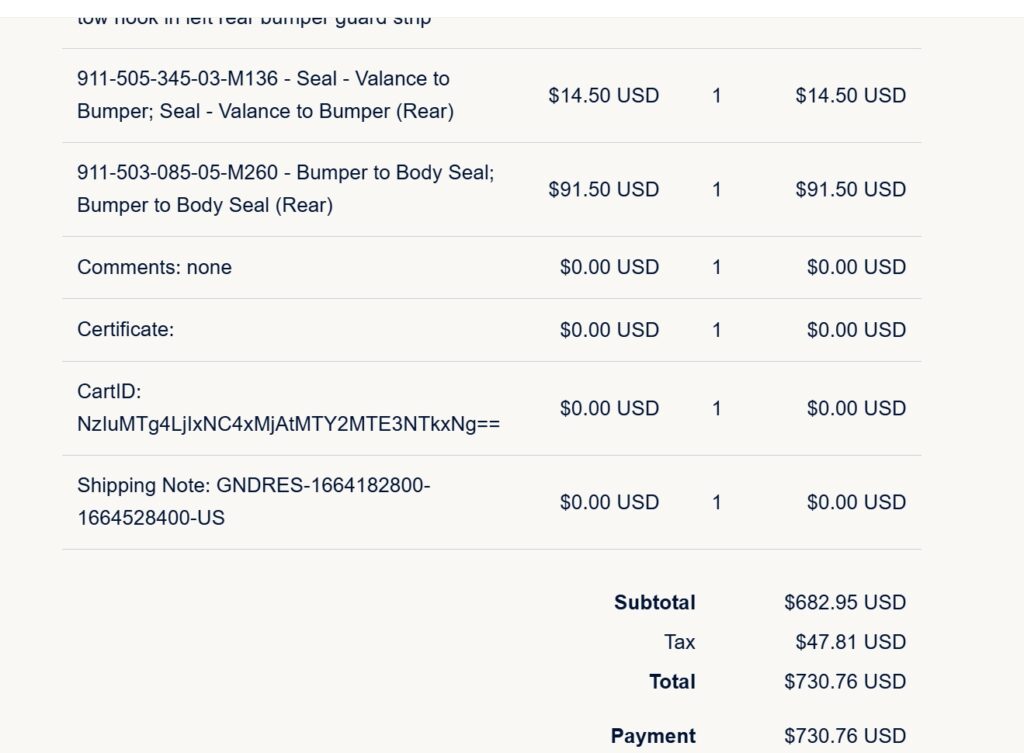

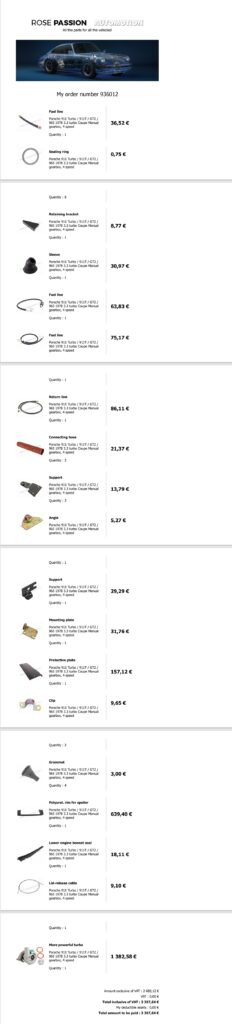

Invoices And Receipts